EPS Pre-expander Machine for Lost Foam Casting: Unleashing Precision and Efficiency

EPS Pre-expander Machine for Lost Foam Casting: Unleashing Precision and Efficiency

Introducing the cutting-edge EPS Pre-expander Machine tailored specifically for the demanding requirements of lost foam casting. This innovative machine offers unparalleled versatility, precision, and automation, making it the ultimate choice for manufacturers working with EPS, FD, and STMMA materials.

Core Features:

Material Versatility: Designed to handle three distinct materials—EPS (Expanded Polystyrene), FD (Foam Densifier), and STMMA (Styrene Methyl Methacrylate)—this machine caters to a wide range of applications, ensuring flexibility and compatibility with various production needs.

Intelligent Control System: Equipped with a PLC (Programmable Logic Controller) and a user-friendly touch screen interface, the EPS Pre-expander Machine offers seamless control over barrel temperature and expansion time. This ensures precise regulation, resulting in uniformly expanded beads with consistent quality.

Automated Feeding System: Incorporating an automatic storage hopper, the machine efficiently dispenses raw materials in precise 1kg increments, eliminating manual intervention and enhancing productivity.

Stable Pressure Management: Featuring a premium Japanese pressure reducing valve, the machine maintains a constant working pressure throughout the expansion process. This ensures stable and reliable performance, further contributing to the high-quality output.

Technical Data:

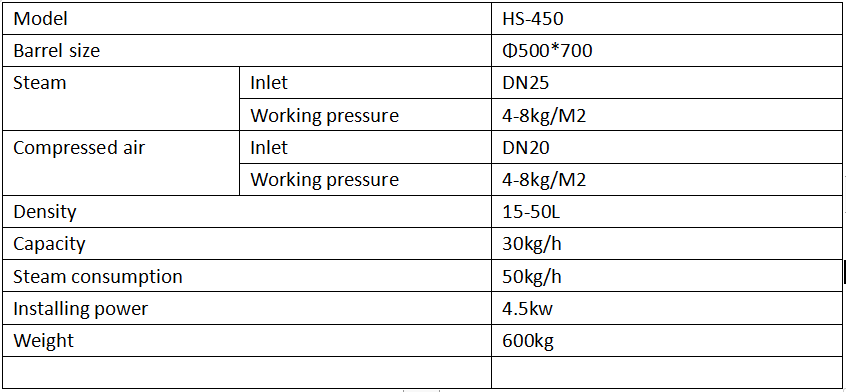

While detailed technical specifications are provided in the accompanying 11.png file for reference, please note that further clarification and confirmation can be obtained directly from the company. The document outlines key parameters such as capacity, temperature ranges, and expansion ratios, ensuring that potential buyers have access to all the necessary information to make an informed decision.

Conclusion:

The EPS Pre-expander Machine for Lost Foam Casting represents the future of precision and efficiency in material processing. Its versatile design, intelligent control system, automated feeding mechanism, and stable pressure management make it the perfect addition to any production line that demands high-quality, uniformly expanded beads. Contact us today to learn more about how this innovative machine can revolutionize your lost foam casting processes.

Main features:

· This machine can be used for 3 kinds of material: EPS、FD and STMMA;

· With PLC and touch screen, can control barrel temperature and expanding time automatically, get uniform beads;

· It adopts automatic storage hopper, each time 1kg raw material to be sent;

· With Japan pressure reducing valve, ensure constant working pressure;

Technical data: