TEL:+86-15010314731

Email: [email protected]

TEL:+86-15010314731

Email: [email protected]

EPS batch machine

EPS Batch Pre-expander Machine: An Innovative Solution for Efficient Production

The EPS (Expanded Polystyrene) Batch Pre-expander Machine is a state-of-the-art equipment designed to revolutionize the production process of EPS beads. This machine combines precision engineering, advanced control systems, and energy-efficient features to deliver unparalleled performance and productivity. In this article, we will delve into the key features, specifications, and benefits of the EPS Batch Pre-expander Machine, making it an ideal choice for manufacturers seeking to optimize their production lines.

Product Overview

The EPS Batch Pre-expander Machine is a fully automated system that efficiently pre-expands EPS beads to a desired density and size. It utilizes advanced technology to ensure consistent and high-quality output, making it suitable for a wide range of applications such as packaging, construction, and insulation.

Key Features

High Production Capacity: The EPS Batch Pre-expander Machine boasts impressive production capacities ranging from 1600Kg/h to 2200Kg/h, depending on the model (SPJY1600G and SPJY2000G). This ensures that manufacturers can meet even the most demanding production schedules with ease.

Precision Control: Equipped with a PID (Proportional-Integral-Derivative) control system, the machine ensures accurate pre-expansion of EPS beads. This system precisely regulates the steam pressure and temperature, resulting in consistent bead density and size.

Energy Efficiency: The machine is equipped with a waste heat collection and reuse system, which significantly reduces energy consumption. Additionally, the fluid bed is equipped with a heater that shortens the aging time, further enhancing energy efficiency.

Advanced Safety Features: Safety is paramount in industrial machinery, and the EPS Batch Pre-expander Machine is no exception. It comes with multiple safety features, including pressure reduction valves and vibration level sensors, to ensure safe and reliable operation.

Customizable Options: The machine offers various optional features, such as an automatic density weighting and printer system, and an automatic EPS Silo System that can be integrated seamlessly with the pre-expander. These options provide manufacturers with the flexibility to tailor the machine to their specific needs.

Durability and Reliability: Constructed with high-quality materials and components, the EPS Batch Pre-expander Machine is built to last. Its sturdy design and robust construction ensure reliable performance over extended periods.

Specifications

Models: SPJY1600G and SPJY2000G

Chamber Diameter: 1600mm (SPJY1600G) and 2000mm (SPJY2000G)

Chamber Height: 2500mm (SPJY1600G) and 2000mm (SPJY2000G)

Tolerance: ±1.5%

Output: 16001800Kg/h (SPJY1600G) and 20002200Kg/h (SPJY2000G) at a density of 15kg/m3

CE Certification: Compliant with international safety standards

Benefits

Increased Efficiency: The fully automated system eliminates manual intervention, reducing labor costs and increasing overall production efficiency.

Improved Quality: Precision control ensures consistent bead density and size, leading to higher-quality end products.

Cost Savings: Energy-efficient features and waste heat collection system help reduce operational costs.

Scalability: With customizable options and modular design, the machine can be easily scaled up to meet future production demands.

Global Support: Manufacturers can rely on a dedicated after-sales service team, including engineers available to service machinery overseas.

Conclusion

The EPS Batch Pre-expander Machine is a cutting-edge solution for manufacturers seeking to optimize their EPS bead production process. Its combination of high production capacity, precision control, energy efficiency, and advanced safety features makes it an invaluable addition to any production line. With customizable options and global support, this machine is poised to become the go-to choice for manufacturers worldwide.

Main features:

· It includes main body, feeding device, weighing system, bed dryer and so on;

· With PLC and touch screen, control barrel temperature , pressure and material level automatically, ensure machine auto running;

· With material weighing system and photoelectric control of material level to reduce foam density error;

· The inner barrel is made of stainless steel plate with high-quality closed structure and high thermal efficiency;

· With Japan steam reducing valve and angle seat valves to control steady steam pressure;

· The electrical components and pneumatic components used in the machines are all well-known brands at home and abroad;

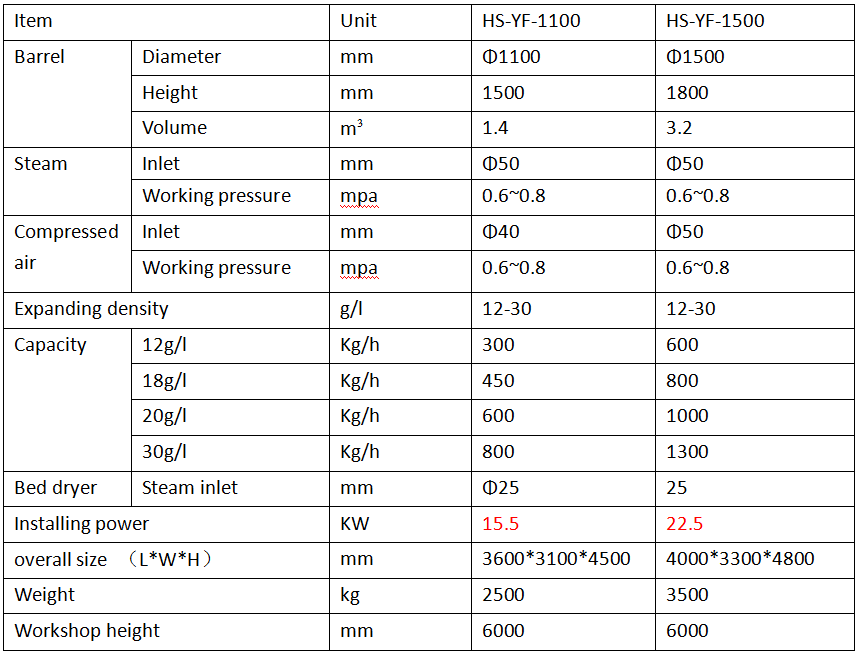

Technical data:

Note: the information is for reference only, further details to be confirmed with the company.

DESCRIBE

This meta description highlights the key features of the EPS Machine - its advanced technology, suitability for various industries, and the benefits it offers in terms of productivity and cost savings. It's concise yet informative, making it ideal for attracting potential customers who are searching for EPS production solutions online.

COPYRIGHT (©) 2032 EPS Machine-EPS Shape Molding Machine EPS Machine-EPS Shape Molding Machine XML Sitemap EPS Machine