Automatic EP Series ETPU/EPP Foam Molding Machine for Insulation Foam Boxes

Product Overview

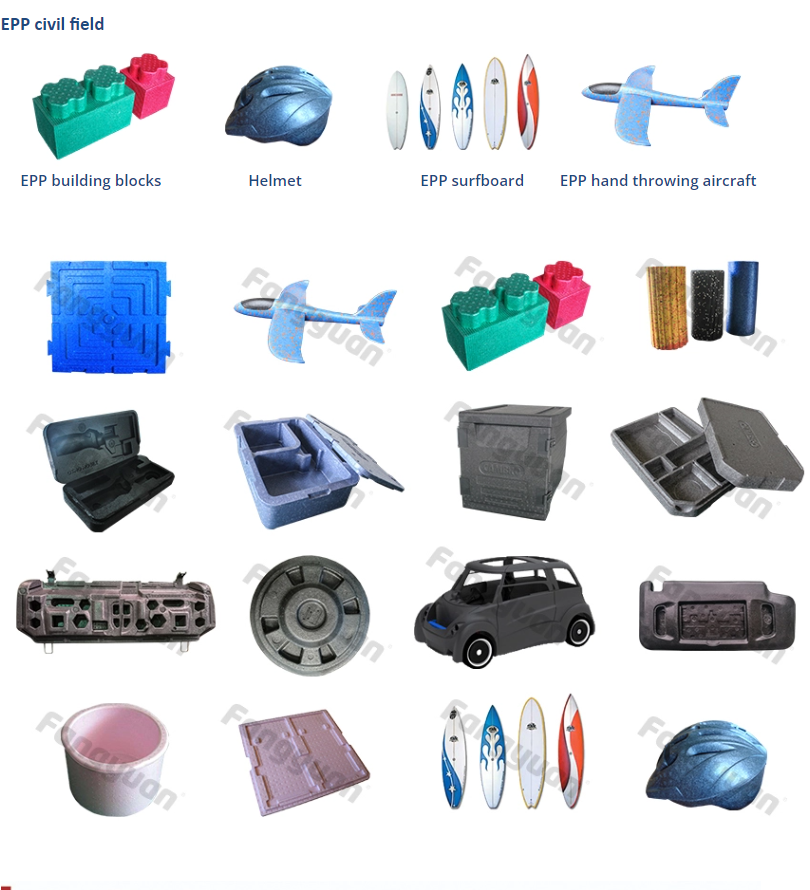

The EP Series ETPU/EPP Foam Molding Machine is an advanced solution designed for the production of high-quality insulation foam boxes. Built to offer exceptional precision, efficiency, and versatility, this machine is perfect for applications requiring durable, lightweight, and well-insulated foam products. Its intelligent control systems and robust construction ensure long-lasting performance, making it ideal for industries such as packaging, logistics, and cold chain solutions.

Key Features

-

Versatile Feeding Methods

The machine supports a range of feeding methods, ensuring optimal material flow and molding consistency:- Pulse Feeding

- Negative Pressure Feeding

- Back Pressure Feeding

- Wind-Assisted Feeding

-

Precise Control with Smart Proportional Valves

The machine is equipped with high-precision smart proportional valves that control critical processes such as feeding, heating, and mold unloading. This ensures accurate material flow and temperature regulation for consistent product quality. -

Integrated Hydraulic Power System

The intensive hydraulic power system combines powering and pressurization in one unit, making maintenance more straightforward and efficient. This system ensures stable, reliable performance during long production runs. -

Separated Positioning Model Frame

The separated positioning model frame design allows for easy mold disassembly, reducing downtime and improving the convenience of maintenance and cleaning. -

Plug-In Water Tank

The machine is equipped with an installed plug-in water tank, ensuring optimal cooling during the molding process and helping to maintain precise temperature control. -

Inching Hydro-Cylinder Mode Locking

The inching hydro-cylinder mode locking mechanism allows for secure mold locking, preventing inaccuracies during the molding process and ensuring high-quality results. -

Self-Equipped Heat-Insulation Steam Chest Template

This feature provides self-insulated steam chest templates, ensuring that heat is evenly distributed throughout the mold and contributing to consistent product quality. -

High Precision and Joint Retention Accuracy

The machine is designed to maintain precise joint retention, with an accuracy margin of less than 0.5mm. This ensures perfect alignment and high-quality finished products every time. -

High-Rigidity Frame for Enduring Production

The high-rigidity frame guarantees durability and stability, even under continuous heavy-duty use. This robust construction ensures that the machine can handle the demands of the EPP industry over the long term. -

Comprehensive Safety Features

The machine is equipped with multiple safety devices to ensure the protection of operators and prevent accidents. These features include emergency stop buttons, protective covers, and safeguards for moving parts.

How It Works

The EP Series ETPU/EPP Foam Molding Machine utilizes advanced molding technology to expand and shape ETPU (Expanded Thermoplastic Polyurethane) or EPP (Expanded Polypropylene) foam into highly durable insulation foam boxes. The various feeding methods ensure optimal material flow into the mold, while the high-precision valves control temperature and pressure during the molding process. The integrated hydraulic system and self-insulated steam chest template ensure that the material is uniformly heated and expanded, creating products with consistent density and shape.

Why Choose Our EPP/ETPU Molding Machine?

- Efficiency: Multiple feeding methods and precise control systems enhance production speed while maintaining product consistency.

- Precision: High-precision valves and an inching hydro-cylinder locking mechanism ensure accurate molding and precise final products.

- Versatility: Ideal for a wide range of applications, including insulation foam boxes for packaging and cold chain logistics.

- Durability: A high-rigidity frame and robust construction ensure long-term reliability and minimal downtime.

- Safety: Comprehensive safety devices protect operators and reduce the risk of workplace accidents.

- Ease of Maintenance: Features like the separated positioning model frame and plug-in water tank simplify maintenance, reducing production downtime.

Conclusion

The Automatic EP Series ETPU/EPP Foam Molding Machine is a reliable, efficient, and high-precision solution for manufacturers looking to produce high-quality insulation foam boxes. With its advanced control systems, versatile feeding methods, and durable construction, this machine ensures consistent, high-performance results for industries requiring protective and insulated packaging solutions. Invest in this advanced technology to enhance your production capabilities and meet the growing demands of the insulation and packaging sectors.

QQ

QQ