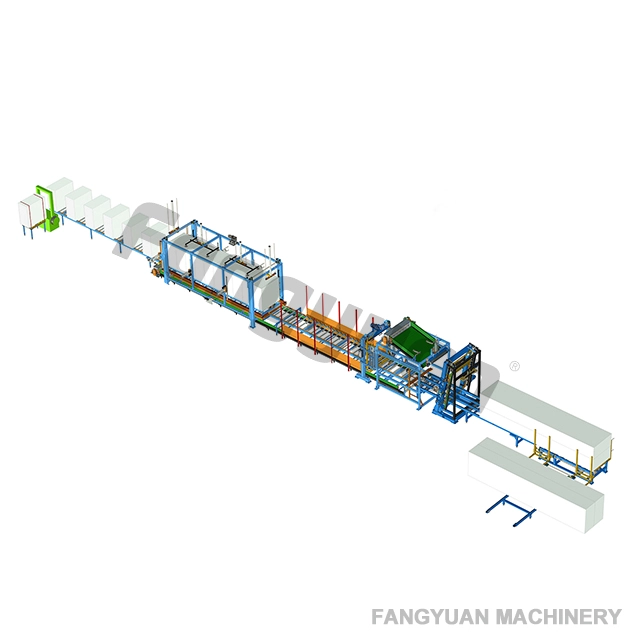

Comprehensive EPS Machine Solutions: Your Trusted Global Supplier As a leading EPS machine supplier, we specialize in the manufacturing, research and development, and after-sales support of advanced equipment for expanded polystyrene (EPS) production. With a strong commitment to innovation and customer satisfaction, we provide end-to-end services, including sales, installation, and technical support, to meet the needs of clients worldwide. Integrated EPS Equipment Manufacturing Our company is at the forefront of EPS machine manufacturing, combining cutting-edge technology with a dedication to quality. Each piece of equipment is designed and built to deliver efficiency, precision, and durability, ensuring optimal performance across a variety of applications. From insulation boards to packaging materials, our EPS machines are versatile and reliable, catering to a wide range of industries. Innovative R&D Capabilities We understand the ever-evolving demands of the global market. That’s why we invest heavily in research and development, continuously improving our EPS equipment to align with industry advancements. Our R&D team focuses on enhancing energy efficiency, reducing production costs, and increasing automation capabilities to ensure our customers stay ahead in their respective fields. Global Sales and Turnkey Installation Services Our expertise extends beyond EPS machine sales. We offer a complete turnkey service, managing everything from equipment delivery to on-site installation and commissioning. Our experienced technical team works closely with clients to ensure seamless integration of the EPS machines into their production processes, minimizing downtime and maximizing efficiency. Reliable After-Sales Support We are committed to building long-term partnerships with our clients. Our after-sales support includes comprehensive maintenance, training, and spare parts supply. Whether you need troubleshooting assistance or routine servicing, our dedicated support team is available to ensure your EPS machines operate at peak performance. Your Global Partner for EPS Machines With decades of experience and a strong international presence, we have established ourselves as a trusted supplier of EPS equipment. Our global reach allows us to serve clients in diverse markets, providing tailored solutions that meet specific regional requirements. Why Choose Us? One-Stop Service: From R&D and manufacturing to sales and installation, we provide an all-in-one solution for EPS machines. Advanced Technology: Our state-of-the-art equipment ensures high productivity, energy efficiency, and consistent quality. Global Expertise: We have successfully delivered EPS machine solutions to clients in numerous countries, adapting to their unique needs and challenges. Comprehensive Support: Our responsive after-sales team guarantees reliable support throughout the lifespan of your equipment.

Whether you’re setting up a new production line or upgrading existing operations, we are here to provide industry-leading EPS machines and unparalleled service. Let us help you achieve greater efficiency, productivity, and success with our integrated solutions.

Model: EPSPE-2000

Key Parameters:

Capacity: 100–200 kg/h

Density Range: 10–35 kg/m³

Steam Pressure: 0.6–0.8 MPa

Power Consumption: 15 kW

Usage Scenarios:

This machine is ideal for pre-expanding EPS beads to the desired density. It’s commonly used in industries like packaging, construction insulation, and protective cushioning.

Features and Functions:

Fully automatic control for precise density adjustment.

Energy-efficient steam system for uniform expansion.

Advanced drying system ensures consistent bead quality.

Compact design for easy installation and maintenance.

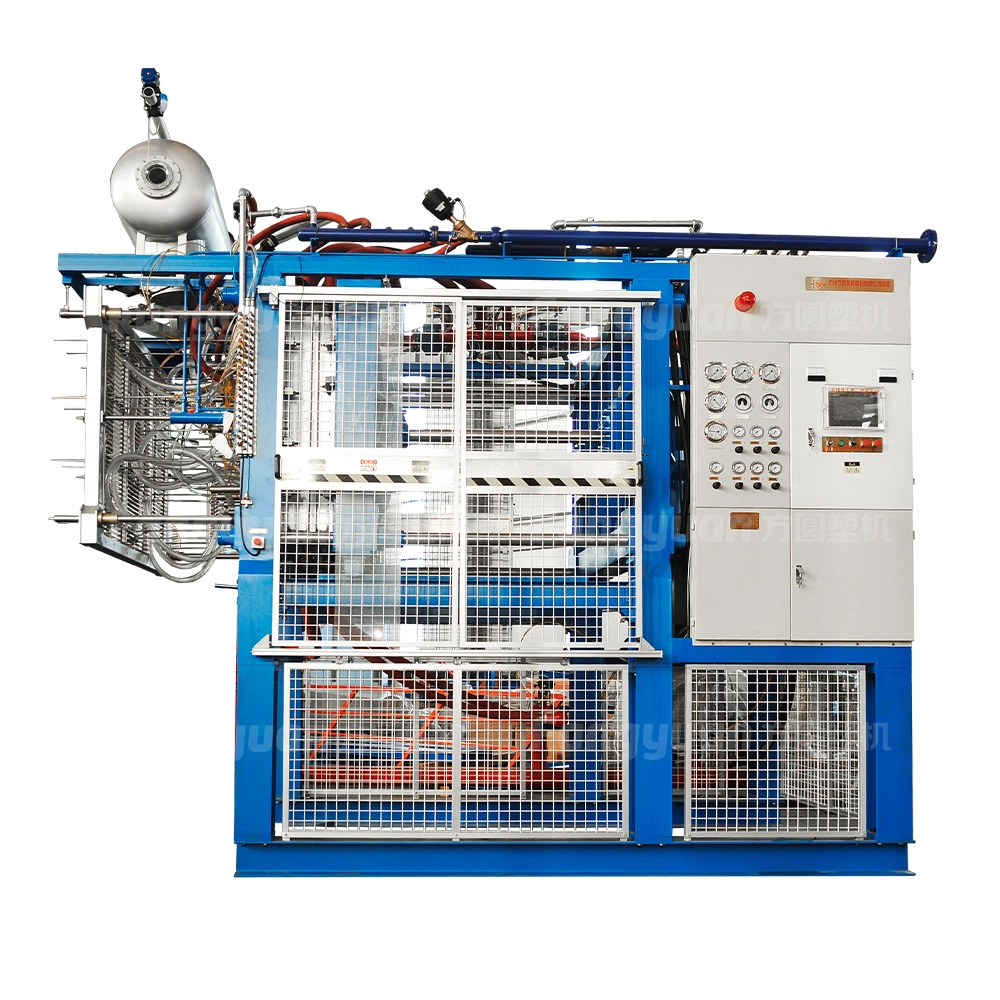

Model: EPSBM-5000

Key Parameters:

Block Size: 5000x1200x600 mm

Cycle Time: 4–6 minutes

Steam Consumption: 10–12 kg/cycle

Power Consumption: 18 kW

Usage Scenarios:

Used for producing large EPS blocks, which can be cut into insulation boards, decorative panels, or other customized shapes for construction and packaging industries.

Features and Functions:

High-precision mold ensures consistent block dimensions.

Efficient cooling system reduces cycle time.

Hydraulic system for smooth and stable operation.

PLC control system for automated operation and high reliability.

Model: EPSM-1200

Key Parameters:

Mold Size: 1200x1000 mm

Cycle Time: 60–120 seconds

Steam Pressure: 0.8 MPa

Power Consumption: 25 kW

Usage Scenarios:

This machine is perfect for manufacturing customized EPS shapes, such as protective packaging, decorative items, and consumer goods.

Features and Functions:

Flexible mold design to accommodate various shapes.

Automatic feeding and ejecting system.

Dual-steam chamber for faster and uniform molding.

Integrated vacuum cooling system for shorter cycles and improved shape precision.

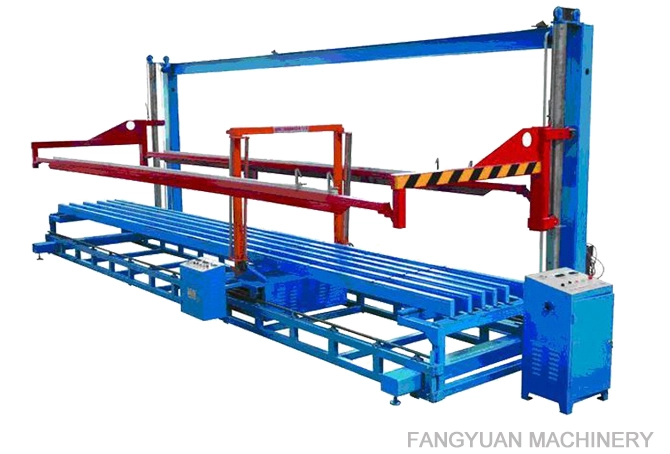

Model: EPSCUT-3000

Key Parameters:

Cutting Size: 3000x1200x600 mm

Wire Tension Control: Automatic

Cutting Speed: Adjustable (10–60 m/min)

Power Consumption: 5 kW

Usage Scenarios:

Designed for cutting large EPS blocks into panels, boards, or intricate designs used in construction, packaging, and crafts.

Features and Functions:

Multi-wire cutting system for simultaneous processing.

High-precision cutting for smooth, accurate edges.

User-friendly interface with programmable cutting patterns.

Sturdy frame and vibration-free operation.

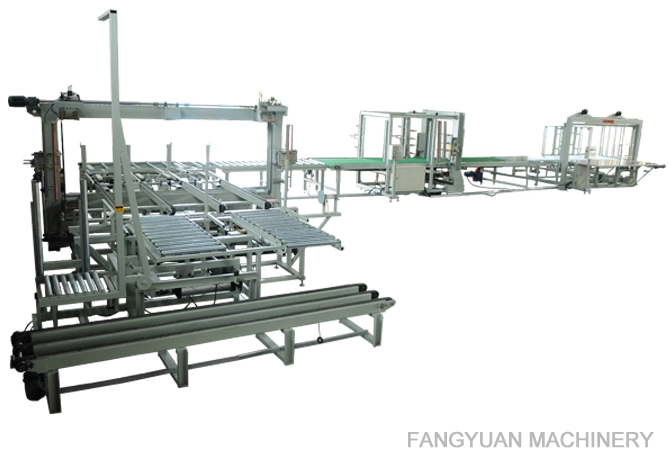

Model: EPSR-1000

Key Parameters:

Capacity: 200–300 kg/h

Output Granule Size: 3–5 mm

Power Consumption: 10 kW

Dimensions: 2500x1200x1800 mm

Usage Scenarios:

Used for recycling EPS waste into reusable granules, this machine is essential for companies focusing on sustainability and cost reduction.

Features and Functions:

Crushes EPS waste into uniform granules.

Dust removal system for cleaner output.

Energy-efficient design with minimal power consumption.

Easy to operate and maintain for long-term use.