Automatic EPS Styrofoam CNC 3D Polystyrene Foam Cutting Machine

Product Description:

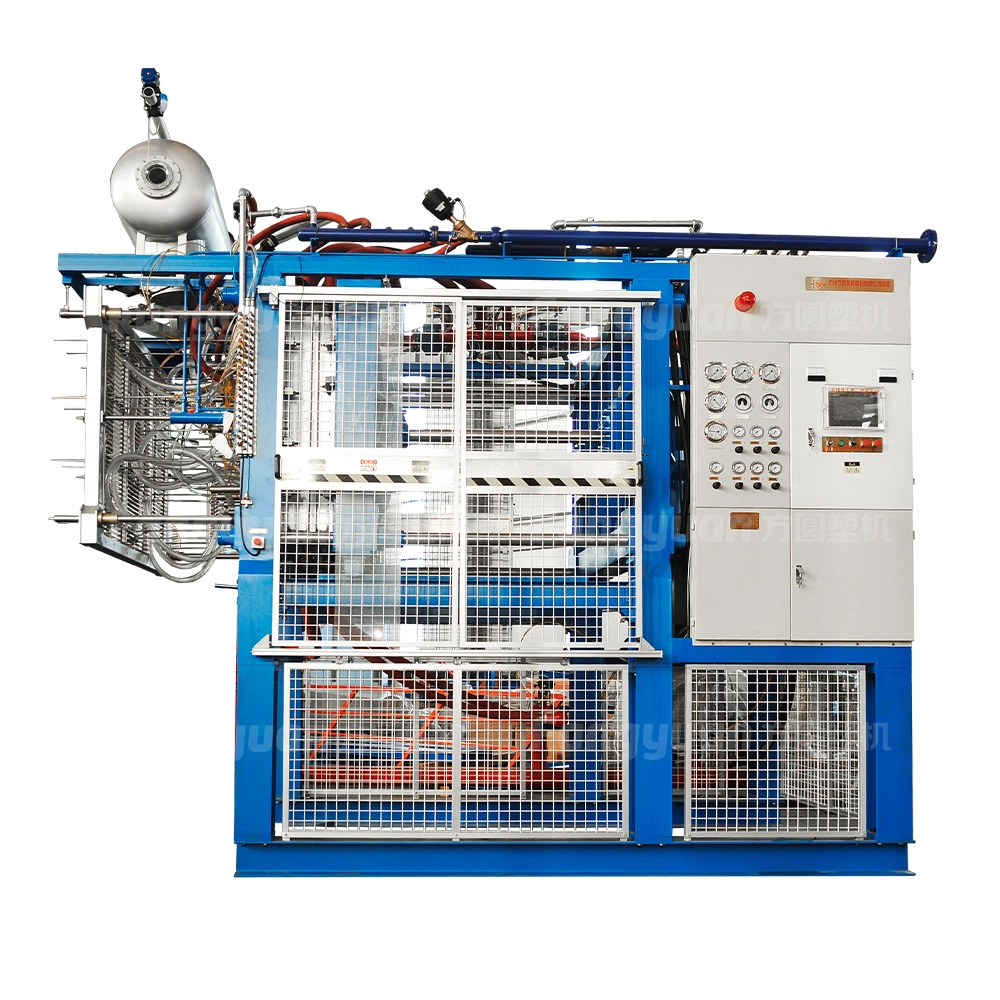

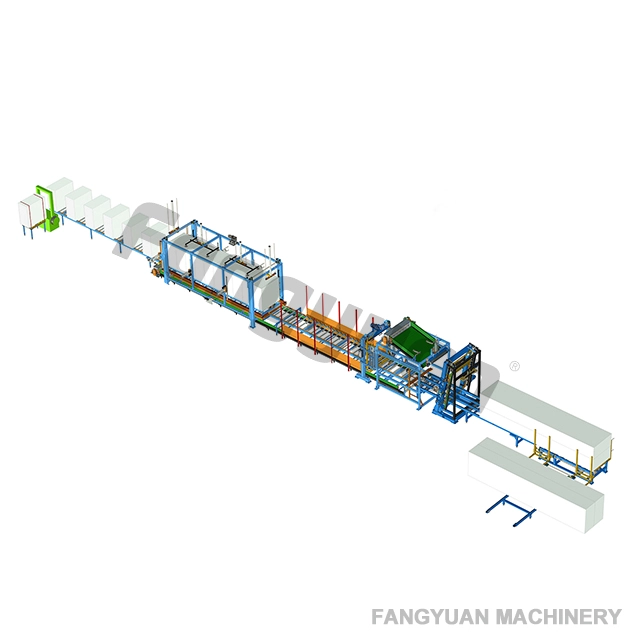

The SPC200/300/400SL/2D/3D EPS CNC Cutting Machine represents an extremely advanced contour cutting solution that is meticulously engineered to deliver outstanding precision and remarkable efficiency. This high-caliber machine not only guarantees top-notch cutting quality but also exhibits high productivity and an extended operational lifespan. These attributes combine to make it a highly dependable option for contemporary industrial applications where accuracy and performance are of utmost importance.

Main Features:

- Robust and Stable Construction:

The machine is constructed with an aluminum frame that is expertly joined together using specialized fastenings. This unique construction imparts remarkable stability to the machine, which in turn enables it to achieve highly precise cutting performance. The solid framework serves as a reliable foundation, minimizing vibrations and ensuring that the cutting tools can operate with utmost accuracy, thereby producing consistently high-quality results. - Stepping Motor for Adjustable Speeds:

Equipped with a sophisticated stepping motor, this CNC cutting machine can handle custom-designed and complex figures with ease. The adjustable speed feature is a key advantage, allowing the operator to fine-tune the cutting process according to the specific requirements of the task at hand. With cutting tolerances as precise as 0.3–0.5 mm, it can execute even the most intricate designs with remarkable accuracy, meeting the exacting standards of modern manufacturing. - Wide Voltage Compatibility:

Featuring a 3KW transformer with an adjustable power output ranging from 0 to 70V, this machine demonstrates excellent adaptability to different voltage conditions. This wide voltage compatibility makes it suitable for various industrial settings, where power fluctuations or different supply voltages may be encountered. It can maintain its performance and functionality regardless of the available power source, ensuring uninterrupted operation and enhanced versatility. - Enhanced Production Capacity:

One of the standout features of this machine is its ability to support up to 20 cutting wires simultaneously. This multi-wire cutting capability significantly boosts the production throughput, especially for large-scale operations. It allows for efficient processing of multiple workpieces or the creation of complex cutting patterns in a single pass, reducing production time and increasing overall output. This makes it an ideal choice for industries with high-volume production demands. - Cutting Stroke Protection:

To ensure the safety and reliability of the cutting process, the machine is equipped with a cutting stroke protection mechanism. This safety feature automatically halts the operation when the cutting stroke exceeds the pre-defined and regulated range. By preventing over-travel of the cutting tools, it not only protects the machine from potential damage but also safeguards the integrity of the workpiece and the operator. This ensures that the cutting process proceeds smoothly and without incident, minimizing the risk of errors and accidents. - Intuitive Control System:

The machine is configured with a 17” screen and a branded computer, providing an intuitive and user-friendly interface for managing and monitoring the design and cutting processes. The cutting software is a highlight, being available in English and packed with a host of powerful features. It includes an automatic memory retention system that stores the progress and settings during power outages, allowing for seamless resumption of work once power is restored. The reverse and rotating cutting functions add flexibility to the design possibilities, while the mirror symmetry cutting and automatic clearance compensation features ensure precise and accurate results every time. - Optional Rotation Platform:

For those applications that demand even greater complexity and intricacy in design, the machine offers an optional rotation platform. This enables 5-axis cutting, which takes the machine's capabilities to a whole new level. It allows for the creation of highly detailed and three-dimensional shapes that would be otherwise difficult or impossible to achieve with a traditional cutting setup. This optional feature significantly enhances the machine's versatility and makes it suitable for a wide range of advanced manufacturing and prototyping tasks.

Related Question and Answer

Question 1: What is the significance of the aluminum frame construction in the SPC200/300/400SL/2D/3D EPS CNC Cutting Machine?

Answer: The aluminum frame connected by specialized fastenings provides superior stability. It reduces vibrations during the cutting process, which is crucial for achieving precise cutting performance. A stable frame ensures that the cutting tools can operate accurately, resulting in consistently high-quality cuts and meeting the tight tolerances required for complex designs.

Question 2: How does the adjustable speed feature of the stepping motor benefit the cutting process?

Answer: The adjustable speed of the stepping motor allows the operator to adapt the cutting process to different materials and design requirements. For softer EPS materials, a slower speed might be used to ensure clean and accurate cuts without causing damage. For more complex and detailed designs, the speed can be adjusted to ensure the cutting tool follows the contours precisely, achieving the desired 0.3–0.5 mm cutting tolerances.

Question 3: What advantages does the wide voltage compatibility offer in industrial applications?

Answer: In industrial settings, power supplies can vary. The wide voltage compatibility (0 - 70V) of the 3KW transformer means the machine can operate effectively regardless of power fluctuations or different voltage sources available. This ensures continuous production without the need for additional voltage regulators or concerns about compatibility issues, enhancing the machine's usability and reliability in diverse industrial environments.

Question 4: Can you explain how the multi-wire cutting capability increases production capacity?

Answer: The ability to support up to 20 cutting wires simultaneously allows the machine to process multiple workpieces or create complex cutting patterns in a single operation. For example, if a production run requires multiple identical EPS foam pieces with a specific shape, the multi-wire cutting can cut them all at once instead of one by one. This significantly reduces the production time per batch and increases the overall output, making it highly efficient for large-scale production.

Question 5: How does the cutting stroke protection mechanism work and why is it important?

Answer: The cutting stroke protection mechanism monitors the movement of the cutting tools. When the cutting stroke exceeds the pre-set limits, it automatically stops the machine's operation. This is important because it prevents damage to the machine components, such as the cutting wires or the frame, which could occur if the tools over-travel. It also protects the workpiece from being damaged due to incorrect cutting actions and ensures the safety of the operator by minimizing the risk of accidents caused by uncontrolled tool movement.

Robust and Stable Construction:

The machine is constructed with an aluminum frame that is expertly joined together using specialized fastenings. This unique construction imparts remarkable stability to the machine, which in turn enables it to achieve highly precise cutting performance. The solid framework serves as a reliable foundation, minimizing vibrations and ensuring that the cutting tools can operate with utmost accuracy, thereby producing consistently high-quality results.

The machine is constructed with an aluminum frame that is expertly joined together using specialized fastenings. This unique construction imparts remarkable stability to the machine, which in turn enables it to achieve highly precise cutting performance. The solid framework serves as a reliable foundation, minimizing vibrations and ensuring that the cutting tools can operate with utmost accuracy, thereby producing consistently high-quality results.

Stepping Motor for Adjustable Speeds:

Equipped with a sophisticated stepping motor, this CNC cutting machine can handle custom-designed and complex figures with ease. The adjustable speed feature is a key advantage, allowing the operator to fine-tune the cutting process according to the specific requirements of the task at hand. With cutting tolerances as precise as 0.3–0.5 mm, it can execute even the most intricate designs with remarkable accuracy, meeting the exacting standards of modern manufacturing.

Equipped with a sophisticated stepping motor, this CNC cutting machine can handle custom-designed and complex figures with ease. The adjustable speed feature is a key advantage, allowing the operator to fine-tune the cutting process according to the specific requirements of the task at hand. With cutting tolerances as precise as 0.3–0.5 mm, it can execute even the most intricate designs with remarkable accuracy, meeting the exacting standards of modern manufacturing.

Wide Voltage Compatibility:

Featuring a 3KW transformer with an adjustable power output ranging from 0 to 70V, this machine demonstrates excellent adaptability to different voltage conditions. This wide voltage compatibility makes it suitable for various industrial settings, where power fluctuations or different supply voltages may be encountered. It can maintain its performance and functionality regardless of the available power source, ensuring uninterrupted operation and enhanced versatility.

Featuring a 3KW transformer with an adjustable power output ranging from 0 to 70V, this machine demonstrates excellent adaptability to different voltage conditions. This wide voltage compatibility makes it suitable for various industrial settings, where power fluctuations or different supply voltages may be encountered. It can maintain its performance and functionality regardless of the available power source, ensuring uninterrupted operation and enhanced versatility.

Enhanced Production Capacity:

One of the standout features of this machine is its ability to support up to 20 cutting wires simultaneously. This multi-wire cutting capability significantly boosts the production throughput, especially for large-scale operations. It allows for efficient processing of multiple workpieces or the creation of complex cutting patterns in a single pass, reducing production time and increasing overall output. This makes it an ideal choice for industries with high-volume production demands.

One of the standout features of this machine is its ability to support up to 20 cutting wires simultaneously. This multi-wire cutting capability significantly boosts the production throughput, especially for large-scale operations. It allows for efficient processing of multiple workpieces or the creation of complex cutting patterns in a single pass, reducing production time and increasing overall output. This makes it an ideal choice for industries with high-volume production demands.

Cutting Stroke Protection:

To ensure the safety and reliability of the cutting process, the machine is equipped with a cutting stroke protection mechanism. This safety feature automatically halts the operation when the cutting stroke exceeds the pre-defined and regulated range. By preventing over-travel of the cutting tools, it not only protects the machine from potential damage but also safeguards the integrity of the workpiece and the operator. This ensures that the cutting process proceeds smoothly and without incident, minimizing the risk of errors and accidents.

To ensure the safety and reliability of the cutting process, the machine is equipped with a cutting stroke protection mechanism. This safety feature automatically halts the operation when the cutting stroke exceeds the pre-defined and regulated range. By preventing over-travel of the cutting tools, it not only protects the machine from potential damage but also safeguards the integrity of the workpiece and the operator. This ensures that the cutting process proceeds smoothly and without incident, minimizing the risk of errors and accidents.

Intuitive Control System:

The machine is configured with a 17” screen and a branded computer, providing an intuitive and user-friendly interface for managing and monitoring the design and cutting processes. The cutting software is a highlight, being available in English and packed with a host of powerful features. It includes an automatic memory retention system that stores the progress and settings during power outages, allowing for seamless resumption of work once power is restored. The reverse and rotating cutting functions add flexibility to the design possibilities, while the mirror symmetry cutting and automatic clearance compensation features ensure precise and accurate results every time.

The machine is configured with a 17” screen and a branded computer, providing an intuitive and user-friendly interface for managing and monitoring the design and cutting processes. The cutting software is a highlight, being available in English and packed with a host of powerful features. It includes an automatic memory retention system that stores the progress and settings during power outages, allowing for seamless resumption of work once power is restored. The reverse and rotating cutting functions add flexibility to the design possibilities, while the mirror symmetry cutting and automatic clearance compensation features ensure precise and accurate results every time.

Optional Rotation Platform:

For those applications that demand even greater complexity and intricacy in design, the machine offers an optional rotation platform. This enables 5-axis cutting, which takes the machine's capabilities to a whole new level. It allows for the creation of highly detailed and three-dimensional shapes that would be otherwise difficult or impossible to achieve with a traditional cutting setup. This optional feature significantly enhances the machine's versatility and makes it suitable for a wide range of advanced manufacturing and prototyping tasks.

For those applications that demand even greater complexity and intricacy in design, the machine offers an optional rotation platform. This enables 5-axis cutting, which takes the machine's capabilities to a whole new level. It allows for the creation of highly detailed and three-dimensional shapes that would be otherwise difficult or impossible to achieve with a traditional cutting setup. This optional feature significantly enhances the machine's versatility and makes it suitable for a wide range of advanced manufacturing and prototyping tasks.

Answer: The aluminum frame connected by specialized fastenings provides superior stability. It reduces vibrations during the cutting process, which is crucial for achieving precise cutting performance. A stable frame ensures that the cutting tools can operate accurately, resulting in consistently high-quality cuts and meeting the tight tolerances required for complex designs.

Answer: The adjustable speed of the stepping motor allows the operator to adapt the cutting process to different materials and design requirements. For softer EPS materials, a slower speed might be used to ensure clean and accurate cuts without causing damage. For more complex and detailed designs, the speed can be adjusted to ensure the cutting tool follows the contours precisely, achieving the desired 0.3–0.5 mm cutting tolerances.

Answer: In industrial settings, power supplies can vary. The wide voltage compatibility (0 - 70V) of the 3KW transformer means the machine can operate effectively regardless of power fluctuations or different voltage sources available. This ensures continuous production without the need for additional voltage regulators or concerns about compatibility issues, enhancing the machine's usability and reliability in diverse industrial environments.

Answer: The ability to support up to 20 cutting wires simultaneously allows the machine to process multiple workpieces or create complex cutting patterns in a single operation. For example, if a production run requires multiple identical EPS foam pieces with a specific shape, the multi-wire cutting can cut them all at once instead of one by one. This significantly reduces the production time per batch and increases the overall output, making it highly efficient for large-scale production.

Answer: The cutting stroke protection mechanism monitors the movement of the cutting tools. When the cutting stroke exceeds the pre-set limits, it automatically stops the machine's operation. This is important because it prevents damage to the machine components, such as the cutting wires or the frame, which could occur if the tools over-travel. It also protects the workpiece from being damaged due to incorrect cutting actions and ensures the safety of the operator by minimizing the risk of accidents caused by uncontrolled tool movement.

QQ

QQ