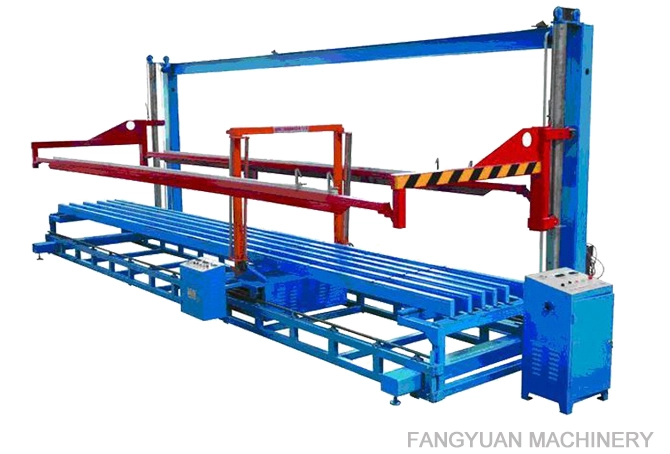

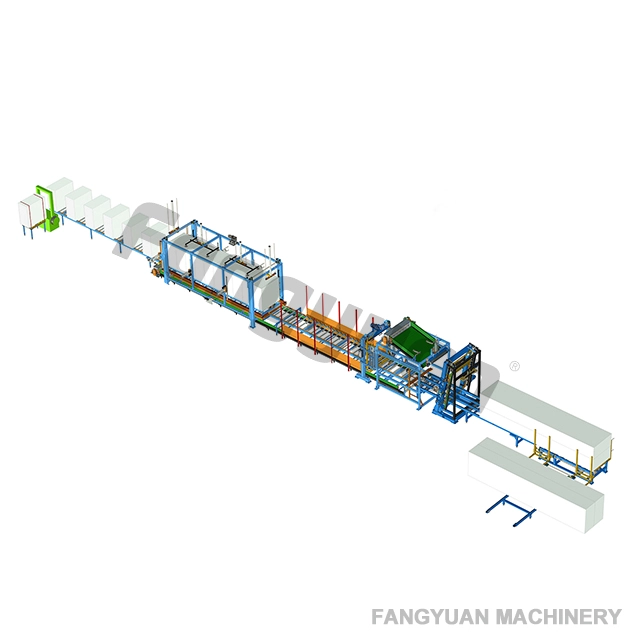

Typical C Series EPS Foam Block Cutting Machine

Product Description:

The SPC200-800C Block Cutting Machine within the C Series represents a highly cost-effective and eminently practical solution, purposefully engineered to address the fundamental EPS cutting requisites. It is distinguished by its dependable performance and straightforward functionality, thereby emerging as an optimal selection for enterprises that are in pursuit of an economical yet proficient cutting machine.

Main Features:

- Comprehensive Features:

This machine encompasses all the advantageous attributes characteristic of the A Series cutting machine. It is constructed with a resilient and durable frame that provides a stable foundation for the cutting operations. The incorporation of a high-capacity transformer endows it with the necessary power supply capabilities to handle various cutting tasks with ease. Additionally, the frequency control mechanism for motor speed allows for precise regulation of the cutting process, ensuring consistent and accurate results. These combined features coalesce to guarantee robust performance and a prolonged operational lifespan, rendering it a reliable asset in any production environment.

- Enhanced Cutting Capability:

In contrast to the A Series, which is restricted to manual width cutting with a solitary wire, the C Series presents a significant advancement in the form of multi-wire cutting capability. This enhanced functionality, when paired with the frequency control for motor speed and a sophisticated voltage adjustment device, empowers the machine to achieve greater precision and enhanced efficiency in the cutting process. It can handle more complex cutting patterns and requirements, thereby expanding the range of applications it can serve and augmenting the overall productivity of the production line.

- Customizable Design:

The EPS thermocol cutting machine within the C Series exhibits a remarkable degree of customizability. It can be meticulously tailored to conform to the specific demands and preferences of individual customers. Whether it pertains to particular cutting dimensions, specific production volumes, or unique operational workflows, this machine can be adjusted and configured accordingly. This flexibility not only accommodates diverse applications but also enables businesses to optimize their production processes in accordance with their own strategic objectives and operational constraints.Can the SPC200-800C Block Cutting Machine cut different shapes and sizes of EPS foam blocks?<button data-testid="message_action_edit" tabindex="0" class="semi-button semi-button-primary semi-button-light container-C7j2CZ size-small-QgdvLx background-white-uG5ycP color-grey-deep-Qeo1ke semi-button-with-icon semi-button-with-icon-only" type="button" aria-disabled="false" aria-describedby="5tblibf" data-popupid="5tblibf" style="-webkit-font-smoothing: antialiased; -webkit-tap-highlight-color: rgba(0, 0, 0, 0); font-family: Inter, -apple-system, BlinkMacSystemFont, "Segoe UI", "PingFang SC", "Hiragino Sans GB", "Microsoft YaHei", "Helvetica Neue", Helvetica, Arial, sans-serif; align-items: center; border-width: 0px; border-style: solid; border-color: transparent; box-shadow: none; display: inline-flex; font-size: 14px; font-weight: 600; height: var(--s-radius-xl,24px); justify-content: center; line-height: 20px; outline: none; padding: 8px; user-select: none; vertical-align: middle; text-wrap: nowrap; transform: scale(var(--semi-transform_scale-none)); transition: background-color var(--semi-transition_duration-none) var(--semi-transition_function-easeIn) var(--semi-transition_delay-none),border var(--semi-transition_duration-none) var(--semi-transition_function-easeIn) var(--semi-transition_delay-none); position: relative; flex-shrink: 0; width: fit-content; min-width: var(--s-radius-xl,24px); margin-right: 12px; overflow-anchor: auto; border-radius: 0px !important; background-image: initial !important; background-position: initial !important; background-size: initial !important; background-repeat: initial !important; background-attachment: initial !important; background-origin: initial !important; background-clip: initial !important;"><svg xmlns="http://www.w3.org/2000/svg" width="16" height="16" fill="currentColor" viewBox="0 0 16 16">

- Enhanced Cutting Capability

- The C Series, to which the SPC200 - 800C belongs, offers multi - wire cutting capability. This is a significant advantage over some other series (such as the A Series which may be limited to manual width cutting with a single wire). The multi - wire cutting function enables more complex and diverse cutting patterns. For example, it can be used to cut blocks into multiple smaller pieces of different sizes simultaneously or to create more intricate shapes by varying the arrangement and movement of the wires.

- Adjustable Features for Precision

- It is equipped with frequency control for motor speed and a voltage adjustment device. These features allow for greater precision and efficiency in the cutting process. The ability to control the motor speed precisely means that the cutting speed and pressure can be adjusted according to the specific requirements of different shapes and sizes. For instance, when cutting a large - sized block into smaller, more detailed shapes, the operator can adjust the motor speed to a slower setting to ensure accurate cuts. The voltage adjustment device also contributes to the overall flexibility of the machine, allowing it to adapt to different cutting conditions and requirements for various block dimensions.

- Customizable Design

- The machine can be tailored to meet specific customer requirements. This customizability implies that it can be configured to handle different shapes and sizes of EPS foam blocks. If a customer needs to cut blocks into a particular geometric shape (such as triangles, hexagons, etc.) or a specific range of sizes for a particular application (like packaging of different products), the machine can be adjusted accordingly. This flexibility makes it suitable for a wide range of applications where the need to cut different shapes and sizes of EPS foam blocks is a common requirement.

Can the SPC200-800C Block Cutting Machine cut curves and angles?

The SPC200 - 800C Block Cutting Machine has features that suggest it can cut curves and angles to a certain extent.

Multi - wire Cutting Capability

The multi - wire cutting feature of the C - Series machine (to which the SPC200 - 800C belongs) provides more flexibility compared to single - wire cutting machines. By carefully controlling the movement and position of the multiple wires, it is possible to approximate curves and angles. For example, if the wires are arranged in a way that they follow a gradually changing path, it can create a curved cut. The operator can adjust the spacing and orientation of the wires to achieve different angular cuts as well.

Precision - Control Mechanisms

The machine is equipped with frequency control for motor speed and a voltage adjustment device. These features play a crucial role in cutting curves and angles. When cutting a curve, a slower and more precisely controlled motor speed can be used to ensure that the wires follow the desired path accurately. The voltage adjustment can also contribute to the stability of the cutting process. By fine - tuning these parameters, the machine can handle the subtleties of cutting curves and angles more effectively.

Customizable Design Aspect

Given that the machine can be customized to meet specific customer requirements, it is possible to configure it to better handle curve and angle cutting. This might involve modifications to the wire - guiding mechanisms or the addition of specialized cutting attachments. For instance, if a customer frequently needs to cut complex curves for decorative EPS foam products, the machine can potentially be adjusted with custom - made guides that help the wires follow the intended curvilinear shapes more precisely.

However, it's important to note that the exact ability to cut complex curves and precise angles may also depend on the skill of the operator, the complexity of the shape, and the specific settings and accessories used with the machine.

- Enhanced Cutting Capability

- The C Series, to which the SPC200 - 800C belongs, offers multi - wire cutting capability. This is a significant advantage over some other series (such as the A Series which may be limited to manual width cutting with a single wire). The multi - wire cutting function enables more complex and diverse cutting patterns. For example, it can be used to cut blocks into multiple smaller pieces of different sizes simultaneously or to create more intricate shapes by varying the arrangement and movement of the wires.

- Adjustable Features for Precision

- It is equipped with frequency control for motor speed and a voltage adjustment device. These features allow for greater precision and efficiency in the cutting process. The ability to control the motor speed precisely means that the cutting speed and pressure can be adjusted according to the specific requirements of different shapes and sizes. For instance, when cutting a large - sized block into smaller, more detailed shapes, the operator can adjust the motor speed to a slower setting to ensure accurate cuts. The voltage adjustment device also contributes to the overall flexibility of the machine, allowing it to adapt to different cutting conditions and requirements for various block dimensions.

- Customizable Design

- The machine can be tailored to meet specific customer requirements. This customizability implies that it can be configured to handle different shapes and sizes of EPS foam blocks. If a customer needs to cut blocks into a particular geometric shape (such as triangles, hexagons, etc.) or a specific range of sizes for a particular application (like packaging of different products), the machine can be adjusted accordingly. This flexibility makes it suitable for a wide range of applications where the need to cut different shapes and sizes of EPS foam blocks is a common requirement.

Can the SPC200-800C Block Cutting Machine cut curves and angles?

The SPC200 - 800C Block Cutting Machine has features that suggest it can cut curves and angles to a certain extent. Multi - wire Cutting Capability The multi - wire cutting feature of the C - Series machine (to which the SPC200 - 800C belongs) provides more flexibility compared to single - wire cutting machines. By carefully controlling the movement and position of the multiple wires, it is possible to approximate curves and angles. For example, if the wires are arranged in a way that they follow a gradually changing path, it can create a curved cut. The operator can adjust the spacing and orientation of the wires to achieve different angular cuts as well. Precision - Control Mechanisms The machine is equipped with frequency control for motor speed and a voltage adjustment device. These features play a crucial role in cutting curves and angles. When cutting a curve, a slower and more precisely controlled motor speed can be used to ensure that the wires follow the desired path accurately. The voltage adjustment can also contribute to the stability of the cutting process. By fine - tuning these parameters, the machine can handle the subtleties of cutting curves and angles more effectively. Customizable Design Aspect Given that the machine can be customized to meet specific customer requirements, it is possible to configure it to better handle curve and angle cutting. This might involve modifications to the wire - guiding mechanisms or the addition of specialized cutting attachments. For instance, if a customer frequently needs to cut complex curves for decorative EPS foam products, the machine can potentially be adjusted with custom - made guides that help the wires follow the intended curvilinear shapes more precisely. However, it's important to note that the exact ability to cut complex curves and precise angles may also depend on the skill of the operator, the complexity of the shape, and the specific settings and accessories used with the machine.

QQ

QQ