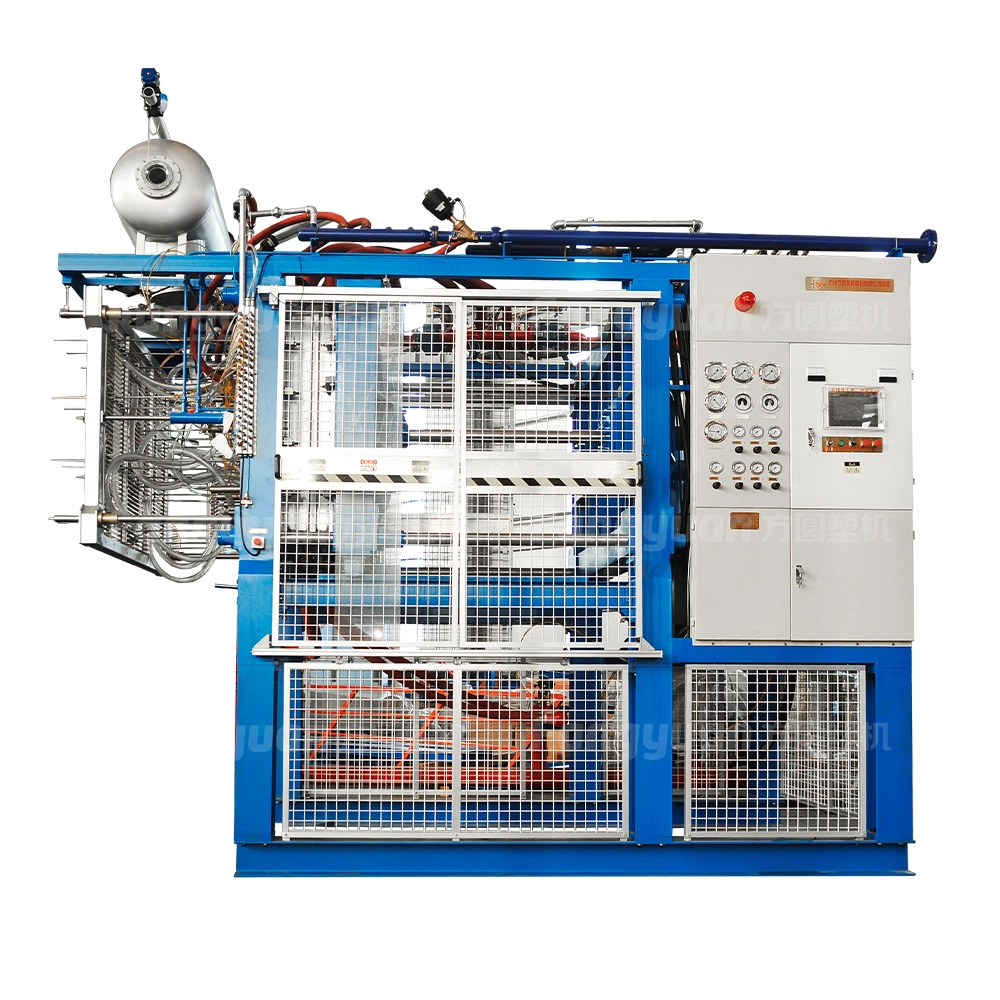

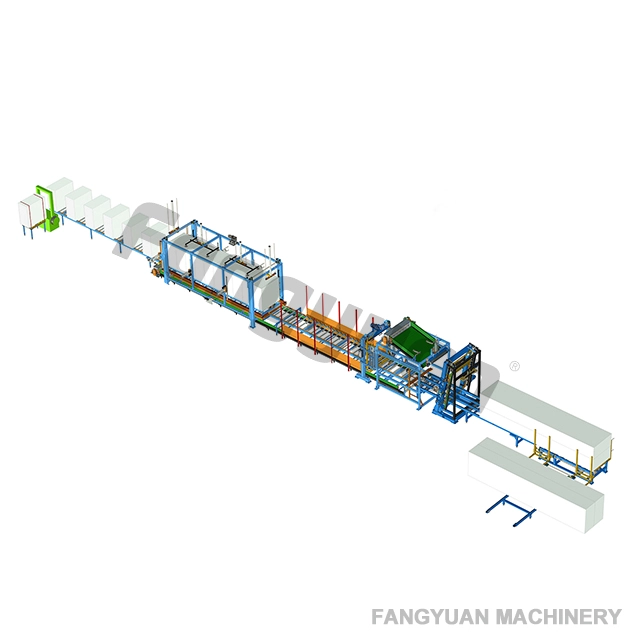

Styrofoam Box Packing Moulding Production Machine for Electric Vehicle Parts Packing

The Styrofoam Box Packing Moulding Production Machine is a state-of-the-art apparatus purposefully engineered to fabricate top-notch, long-lasting packaging solutions for electric vehicle (EV) parts. Boasting a plethora of advanced features and an optimized design, this machine guarantees outstanding performance, remarkable energy efficiency, and effortless operation.

Key Features

1. Robust Machine Structure

Reinforced Frame Design: The frame of the machine is meticulously welded onto robust 16/20 mm steel plates, endowing it with extraordinary strength and unwavering stability. This solid foundation enables the machine to endure the rigors of continuous production and maintain its structural integrity over an extended period.

High "H" Profile Machine Legs: The incorporation of high "H" profile machine legs not only simplifies the installation process but also provides enhanced support. With just a prepared floor foundation, the machine can be easily set up, saving both time and effort.

2. High-Precision Filling System

Efficient Filling Mechanism: The filling system combines normal pressure and vacuum-assisted high-pressure filling, ensuring an optimal distribution of material. This synergy allows for a seamless and efficient transfer of the styrofoam material into the molds, minimizing waste and maximizing the quality of the final product.

44 Filling Outlets with Double Rotation Chamber Discharge: The presence of 44 precisely designed filling outlets, along with a double rotation chamber discharge system and level sensor control, enables a consistent and highly accurate material flow. This level of precision is crucial in producing styrofoam boxes with uniform density and thickness, which are essential for providing reliable protection to EV parts.

3. Advanced Steam System

Energy-Saving Technology: The machine is equipped with a balance PID control valve and a German gauge, which work in tandem to achieve precise steam regulation. This advanced technology results in a significant reduction in steam consumption, approximately 20% less than that of traditional A/B type machines. By optimizing steam usage, the machine not only cuts down on energy costs but also contributes to a more sustainable manufacturing process.

4. Efficient Cooling System

Vacuum-Based Cooling: A large vacuum pump and vertical tank with a top-mounted cooling water spray constitute the core of the cooling system. Vacuum cooling is the predominant method, with water cooling limited to a brief 8 - 12 seconds. This approach effectively reduces the water content of the final product to below 10%, enhancing the dimensional stability and quality of the styrofoam boxes.

5. Enhanced Drainage System

Accelerated Heating and Cooling: The machine features large inlets and outlets for steam and drainage, including an 8 - 1” steam inlet and 6/8 - 2” drainage outlets. A 6” drainage pipe with a butterfly valve ensures rapid heating and drainage, thereby streamlining the production cycle and increasing overall productivity.

6. Intelligent Control System

User-Friendly Operation: The integration of a Mitsubishi PLC and a Schneider touchscreen offers operators an intuitive and efficient control interface. This allows for easy monitoring and adjustment of various parameters, ensuring smooth and seamless operation.

Long-Distance Balance Valves: Long-distance balance valves are employed to regulate air cooling, steam, de-molding, and filling pressure, enhancing the precision of the manufacturing process. This comprehensive control system minimizes the potential for errors and ensures the production of high-quality styrofoam boxes.

Premium Components: The machine is outfitted with top-quality electronic parts sourced from renowned brands, ensuring long-term stability and reliability. These high-grade components reduce the likelihood of breakdowns and maintenance issues, maximizing the machine's uptime and productivity.

Why Choose This Machine?

The Styrofoam Box Packing Moulding Production Machine is the quintessential choice for manufacturing packaging customized to the specific requirements of electric vehicle parts. Its robust construction withstands the demands of heavy-duty production, while its energy-efficient systems curtail operating costs. The advanced controls and high-precision mechanisms ensure the consistent production of top-quality styrofoam boxes, providing optimal protection for EV parts and bolstering the overall efficiency of the packaging process.

Related Question and Answer

Question 1: How does the welded steel plate frame contribute to the machine's durability and performance?

Answer: The welded 16/20 mm steel plates form a rigid and stable structure. It can withstand the mechanical stresses and vibrations generated during the production process. This stability is crucial for maintaining the alignment and precision of the molds, ensuring that each styrofoam box is formed with accurate dimensions. Additionally, the durable frame reduces the risk of structural damage, which in turn minimizes the need for repairs and downtime, enhancing the overall performance and longevity of the machine.

Question 2: What is the significance of the combination of normal pressure and vacuum-assisted high-pressure filling in the filling system?

Answer: The normal pressure filling initiates the material flow, while the vacuum-assisted high-pressure filling helps to overcome any resistance or blockages. This combination ensures a more complete and uniform filling of the molds. It allows for better control over the density and distribution of the styrofoam material, resulting in boxes with improved structural integrity and insulation properties. This is especially important for packaging EV parts, as it provides better protection against shocks and temperature changes.

Question 3: How does the balance PID control valve and German gauge in the steam system achieve energy savings?

Answer: The balance PID control valve and German gauge work in harmony to precisely monitor and adjust the steam pressure and flow. By maintaining the steam at the optimal level, the machine avoids over-steaming or under-steaming. Over-steaming leads to wasted energy, while under-steaming may result in incomplete molding. This precise control ensures that only the necessary amount of steam is used, reducing steam consumption by about 20% compared to traditional systems. This energy-efficient operation not only reduces costs but also aligns with sustainable manufacturing practices.

Question 4: Why is vacuum cooling the primary method and how does it affect the quality of the styrofoam boxes?

Answer: Vacuum cooling is the primary method because it is more effective in removing heat and reducing the water content. By limiting water cooling to 8 - 12 seconds and relying mainly on vacuum cooling, the water content of the product can be kept below 10%. This low water content improves the dimensional stability of the styrofoam boxes, reducing the chances of warping or shrinking. It also enhances the thermal insulation performance, which is crucial for protecting EV parts from temperature fluctuations during transportation and storage.

Question 5: How does the intelligent control system enhance the production process?

Answer: The intelligent control system, with its Mitsubishi PLC and Schneider touchscreen, allows for easy and precise adjustment of various parameters. Operators can quickly set and modify settings such as temperature, pressure, and filling levels. The long-distance balance valves for air cooling, steam, de-molding, and filling pressure ensure that these processes are coordinated smoothly. This reduces the potential for human error, speeds up production cycles, and improves the consistency and quality of the styrofoam boxes produced. The use of premium electronic components further enhances the system's reliability, minimizing downtime and maximizing productivity.

QQ

QQ