Flexible EPS Foam Recycling Pelletizing Machine

Product Description:

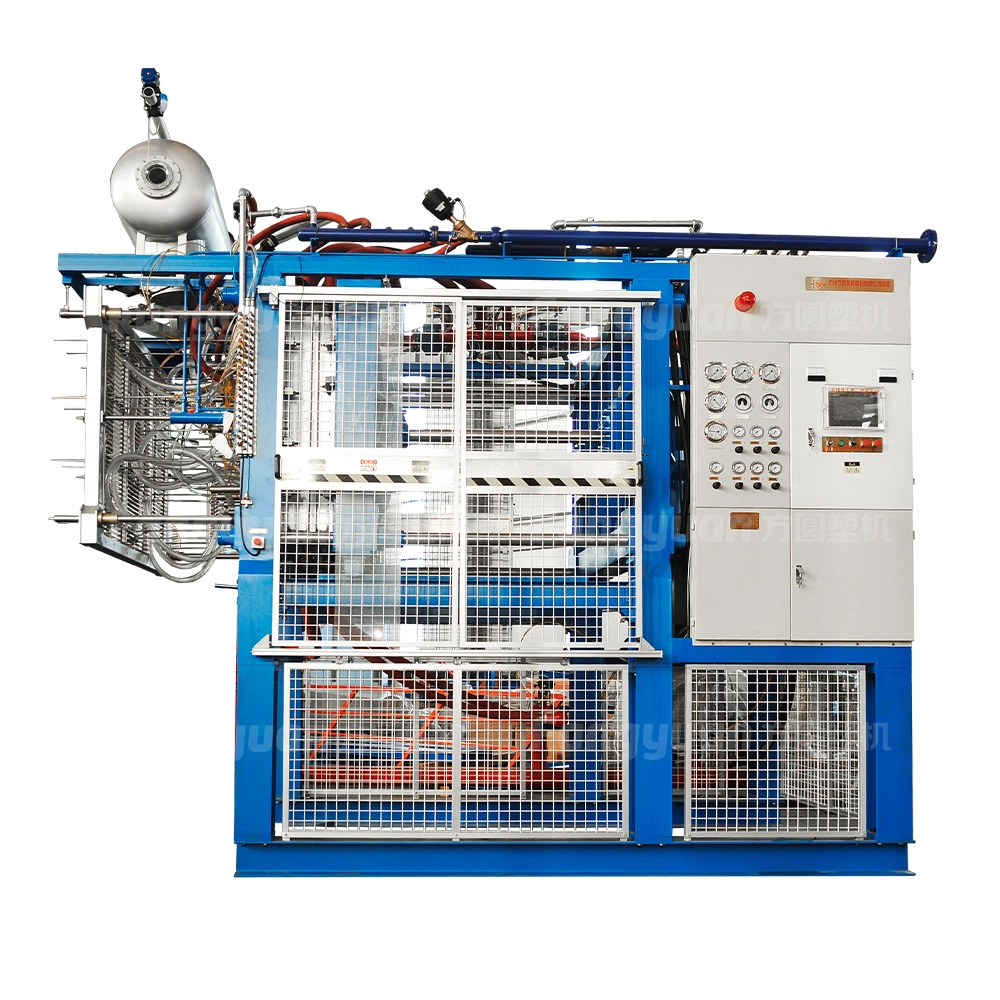

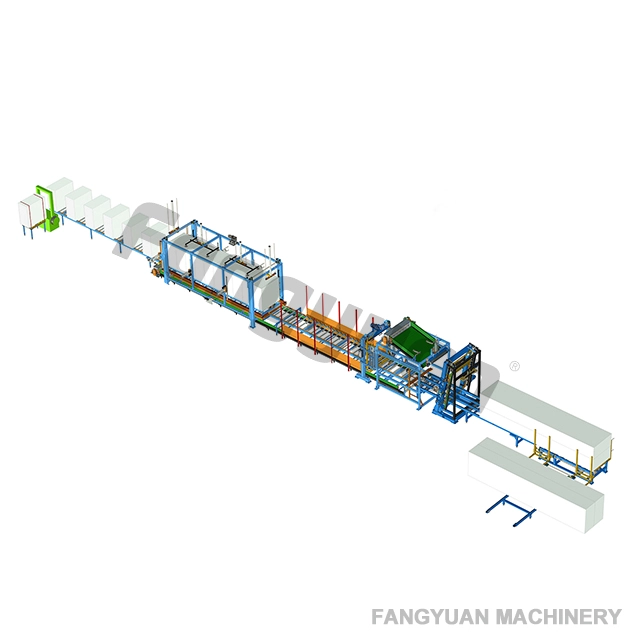

The Flexible EPS Foam Recycling Pelletizing Machine presents itself as a compact yet highly efficient solution that is specifically engineered to convert EPS scrap into reusable PS material. Through its revolutionary and innovative design, this machine actively promotes sustainable production by ingeniously transforming waste materials into valuable resources. This is achieved via a series of well-orchestrated processes including melting, extrusion, and cooling, which work in harmony to breathe new life into what was once considered discarded EPS waste.

Main Features:

- Compact Structure:

This machine is meticulously crafted with a space-saving concept in mind. Its streamlined and efficient layout not only optimizes the use of available space but also contributes to enhanced overall functionality. The compact design makes it an ideal choice for various industrial settings where floor space is a precious commodity, without compromising on its performance capabilities. - High Production Capacity:

It showcases an impressive ability to handle large volumes of EPS waste. This high production capacity is a key attribute that ensures businesses can achieve optimal productivity levels. Whether dealing with significant amounts of post-production waste or accumulated EPS scraps from different sources, the machine can effectively process them, thereby facilitating a continuous and efficient recycling operation. - Energy-Efficient and Eco-Friendly:

The Flexible EPS Foam Recycling Pelletizing Machine is a champion of energy conservation and environmental stewardship. It is designed to minimize energy consumption during the recycling process, which not only reduces operational costs but also lessens the carbon footprint associated with waste management. By recycling EPS waste in real-time, it actively contributes to the reduction of landfill waste and the conservation of natural resources, making it a sustainable solution that aligns with modern environmental goals. - Reliable Recycling Process:

It employs a highly reliable recycling process that consistently converts EPS scrap into high-quality PS material. This recycled PS material meets the stringent quality requirements necessary for a wide range of applications. The machine's precision and consistency in the recycling process ensure that the end-product is of a standard that can be effectively utilized in various manufacturing processes, thereby adding value to the recycled material and closing the loop in the circular economy.

Applications:

- Material Conversion:

Utilizing advanced melting, extrusion, and cooling technologies, the machine performs a remarkable transformation of EPS scrap into PS material. This conversion process is carefully calibrated to ensure the integrity and quality of the resulting PS material. The use of state-of-the-art technology enables the machine to handle different types of EPS waste and produce a uniform and consistent PS product that can be further processed or used directly in downstream applications. - End-Use Products:

The recycled PS material obtained from this machine has a broad spectrum of applications. It can be used in the manufacturing of diverse plastic products, ranging from consumer goods to industrial components. Additionally, it is a viable option for the production of XPS blocks, which are widely used in the construction and insulation industries. This versatility in end-use products not only showcases the value of the recycled material but also emphasizes the machine's significance in supporting circular production practices.

In conclusion, the Flexible EPS Foam Recycling Pelletizing Machine is an indispensable asset for businesses that are committed to enhancing their sustainability efforts, reducing waste generation, and improving overall production efficiency. It offers a comprehensive solution that addresses both environmental and economic concerns, making it a key player in the modern recycling and manufacturing landscape.

Compact Structure:

This machine is meticulously crafted with a space-saving concept in mind. Its streamlined and efficient layout not only optimizes the use of available space but also contributes to enhanced overall functionality. The compact design makes it an ideal choice for various industrial settings where floor space is a precious commodity, without compromising on its performance capabilities.

This machine is meticulously crafted with a space-saving concept in mind. Its streamlined and efficient layout not only optimizes the use of available space but also contributes to enhanced overall functionality. The compact design makes it an ideal choice for various industrial settings where floor space is a precious commodity, without compromising on its performance capabilities.

High Production Capacity:

It showcases an impressive ability to handle large volumes of EPS waste. This high production capacity is a key attribute that ensures businesses can achieve optimal productivity levels. Whether dealing with significant amounts of post-production waste or accumulated EPS scraps from different sources, the machine can effectively process them, thereby facilitating a continuous and efficient recycling operation.

It showcases an impressive ability to handle large volumes of EPS waste. This high production capacity is a key attribute that ensures businesses can achieve optimal productivity levels. Whether dealing with significant amounts of post-production waste or accumulated EPS scraps from different sources, the machine can effectively process them, thereby facilitating a continuous and efficient recycling operation.

Energy-Efficient and Eco-Friendly:

The Flexible EPS Foam Recycling Pelletizing Machine is a champion of energy conservation and environmental stewardship. It is designed to minimize energy consumption during the recycling process, which not only reduces operational costs but also lessens the carbon footprint associated with waste management. By recycling EPS waste in real-time, it actively contributes to the reduction of landfill waste and the conservation of natural resources, making it a sustainable solution that aligns with modern environmental goals.

The Flexible EPS Foam Recycling Pelletizing Machine is a champion of energy conservation and environmental stewardship. It is designed to minimize energy consumption during the recycling process, which not only reduces operational costs but also lessens the carbon footprint associated with waste management. By recycling EPS waste in real-time, it actively contributes to the reduction of landfill waste and the conservation of natural resources, making it a sustainable solution that aligns with modern environmental goals.

Reliable Recycling Process:

It employs a highly reliable recycling process that consistently converts EPS scrap into high-quality PS material. This recycled PS material meets the stringent quality requirements necessary for a wide range of applications. The machine's precision and consistency in the recycling process ensure that the end-product is of a standard that can be effectively utilized in various manufacturing processes, thereby adding value to the recycled material and closing the loop in the circular economy.

It employs a highly reliable recycling process that consistently converts EPS scrap into high-quality PS material. This recycled PS material meets the stringent quality requirements necessary for a wide range of applications. The machine's precision and consistency in the recycling process ensure that the end-product is of a standard that can be effectively utilized in various manufacturing processes, thereby adding value to the recycled material and closing the loop in the circular economy.

Material Conversion:

Utilizing advanced melting, extrusion, and cooling technologies, the machine performs a remarkable transformation of EPS scrap into PS material. This conversion process is carefully calibrated to ensure the integrity and quality of the resulting PS material. The use of state-of-the-art technology enables the machine to handle different types of EPS waste and produce a uniform and consistent PS product that can be further processed or used directly in downstream applications.

Utilizing advanced melting, extrusion, and cooling technologies, the machine performs a remarkable transformation of EPS scrap into PS material. This conversion process is carefully calibrated to ensure the integrity and quality of the resulting PS material. The use of state-of-the-art technology enables the machine to handle different types of EPS waste and produce a uniform and consistent PS product that can be further processed or used directly in downstream applications.

End-Use Products:

The recycled PS material obtained from this machine has a broad spectrum of applications. It can be used in the manufacturing of diverse plastic products, ranging from consumer goods to industrial components. Additionally, it is a viable option for the production of XPS blocks, which are widely used in the construction and insulation industries. This versatility in end-use products not only showcases the value of the recycled material but also emphasizes the machine's significance in supporting circular production practices.

The recycled PS material obtained from this machine has a broad spectrum of applications. It can be used in the manufacturing of diverse plastic products, ranging from consumer goods to industrial components. Additionally, it is a viable option for the production of XPS blocks, which are widely used in the construction and insulation industries. This versatility in end-use products not only showcases the value of the recycled material but also emphasizes the machine's significance in supporting circular production practices.

Questions related to the working principle

- Question: How does the Flexible EPS Foam Recycling Pelletizing Machine convert EPS foam into PS pellets?

- Answer: The machine mainly achieves the conversion through three key steps: melting, extrusion, and cooling. Firstly, the EPS foam waste is fed into the heating chamber of the machine. Under the action of heating, the EPS foam will be heated to a molten state, forming a liquid PS material. Then, the liquid PS material is extruded through the extrusion device to form long strips. Finally, through the action of the cooling system, the long strips of PS material are cooled and solidified, and then cut into uniform PS pellets by the pelletizing device.

- Question: How does the Flexible EPS Foam Recycling Pelletizing Machine convert EPS foam into PS pellets?

- Answer: The machine mainly achieves the conversion through three key steps: melting, extrusion, and cooling. Firstly, the EPS foam waste is fed into the heating chamber of the machine. Under the action of heating, the EPS foam will be heated to a molten state, forming a liquid PS material. Then, the liquid PS material is extruded through the extrusion device to form long strips. Finally, through the action of the cooling system, the long strips of PS material are cooled and solidified, and then cut into uniform PS pellets by the pelletizing device.

Questions related to equipment performance

- Question: What is the production efficiency of the Flexible EPS Foam Recycling Pelletizing Machine?

- Answer: It has relatively high production efficiency and is capable of processing a large amount of EPS foam waste within a unit time. The specific production capacity may vary depending on factors such as the model, specification, and operating conditions of the equipment, but generally, it can meet the production needs of small and medium-sized enterprises.

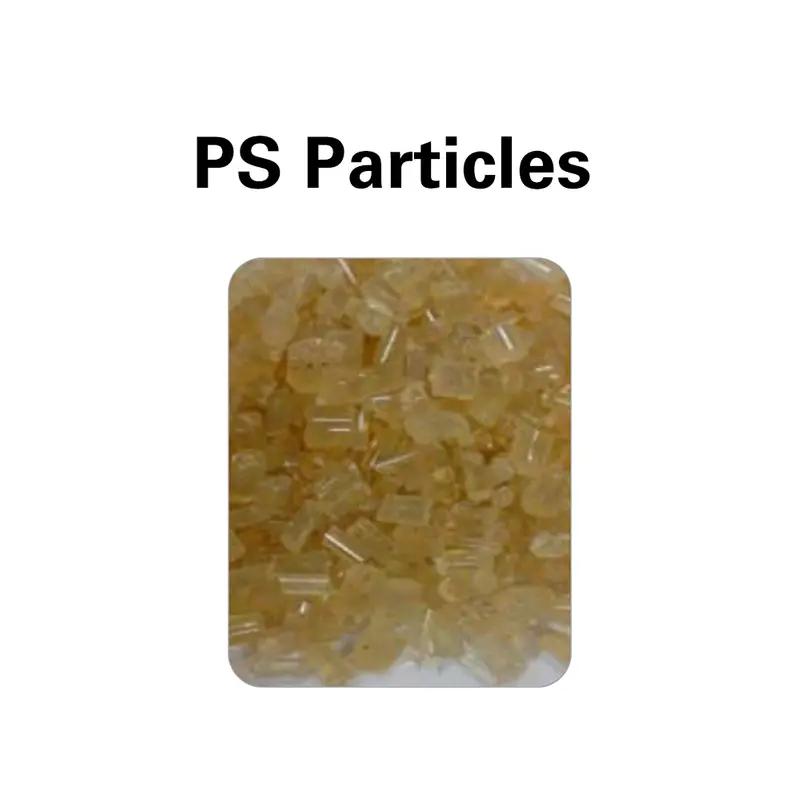

- Question: What is the quality of the PS pellets produced by this machine?

- Answer: The PS pellets produced by this machine are of high quality, featuring uniform size, regular shape, and high purity, and can be widely used in the manufacturing of various plastic products and XPS blocks.

- Question: What is the production efficiency of the Flexible EPS Foam Recycling Pelletizing Machine?

- Answer: It has relatively high production efficiency and is capable of processing a large amount of EPS foam waste within a unit time. The specific production capacity may vary depending on factors such as the model, specification, and operating conditions of the equipment, but generally, it can meet the production needs of small and medium-sized enterprises.

- Question: What is the quality of the PS pellets produced by this machine?

- Answer: The PS pellets produced by this machine are of high quality, featuring uniform size, regular shape, and high purity, and can be widely used in the manufacturing of various plastic products and XPS blocks.

Questions related to operation and maintenance

- Question: What safety precautions should be taken when operating the Flexible EPS Foam Recycling Pelletizing Machine?

- Answer: When operating, make sure that the equipment is properly grounded to prevent electric shock accidents. During the operation of the machine, it is strictly prohibited to open the protective doors or reach into the interior of the machine to avoid scalding or mechanical injuries. Meanwhile, regular inspections and maintenance of the equipment should be carried out to ensure its normal operation.

- Question: How to conduct daily maintenance on the Flexible EPS Foam Recycling Pelletizing Machine?

- Answer: Daily maintenance includes regularly cleaning the dust and debris on the surface of the equipment, checking whether the connections of various components are loose, inspecting and maintaining the heating system, extrusion system, and cooling system to ensure their normal operation. It is also necessary to regularly replace consumable parts such as lubricating oil and filters to extend the service life of the equipment.

- Question: What safety precautions should be taken when operating the Flexible EPS Foam Recycling Pelletizing Machine?

- Answer: When operating, make sure that the equipment is properly grounded to prevent electric shock accidents. During the operation of the machine, it is strictly prohibited to open the protective doors or reach into the interior of the machine to avoid scalding or mechanical injuries. Meanwhile, regular inspections and maintenance of the equipment should be carried out to ensure its normal operation.

- Question: How to conduct daily maintenance on the Flexible EPS Foam Recycling Pelletizing Machine?

- Answer: Daily maintenance includes regularly cleaning the dust and debris on the surface of the equipment, checking whether the connections of various components are loose, inspecting and maintaining the heating system, extrusion system, and cooling system to ensure their normal operation. It is also necessary to regularly replace consumable parts such as lubricating oil and filters to extend the service life of the equipment.

Questions related to application fields

- Question: In which fields can the recycled PS pellets be used?

- Answer: The recycled PS pellets have a wide range of applications. They can be used in the manufacturing of various plastic products, such as plastic films, plastic pipes, and plastic containers. They can also be used to produce XPS blocks for building insulation, packaging, and other fields. In addition, they can also be used in some other special fields, such as making handicrafts and filling materials.

- Question: In which fields can the recycled PS pellets be used?

- Answer: The recycled PS pellets have a wide range of applications. They can be used in the manufacturing of various plastic products, such as plastic films, plastic pipes, and plastic containers. They can also be used to produce XPS blocks for building insulation, packaging, and other fields. In addition, they can also be used in some other special fields, such as making handicrafts and filling materials.

QQ

QQ