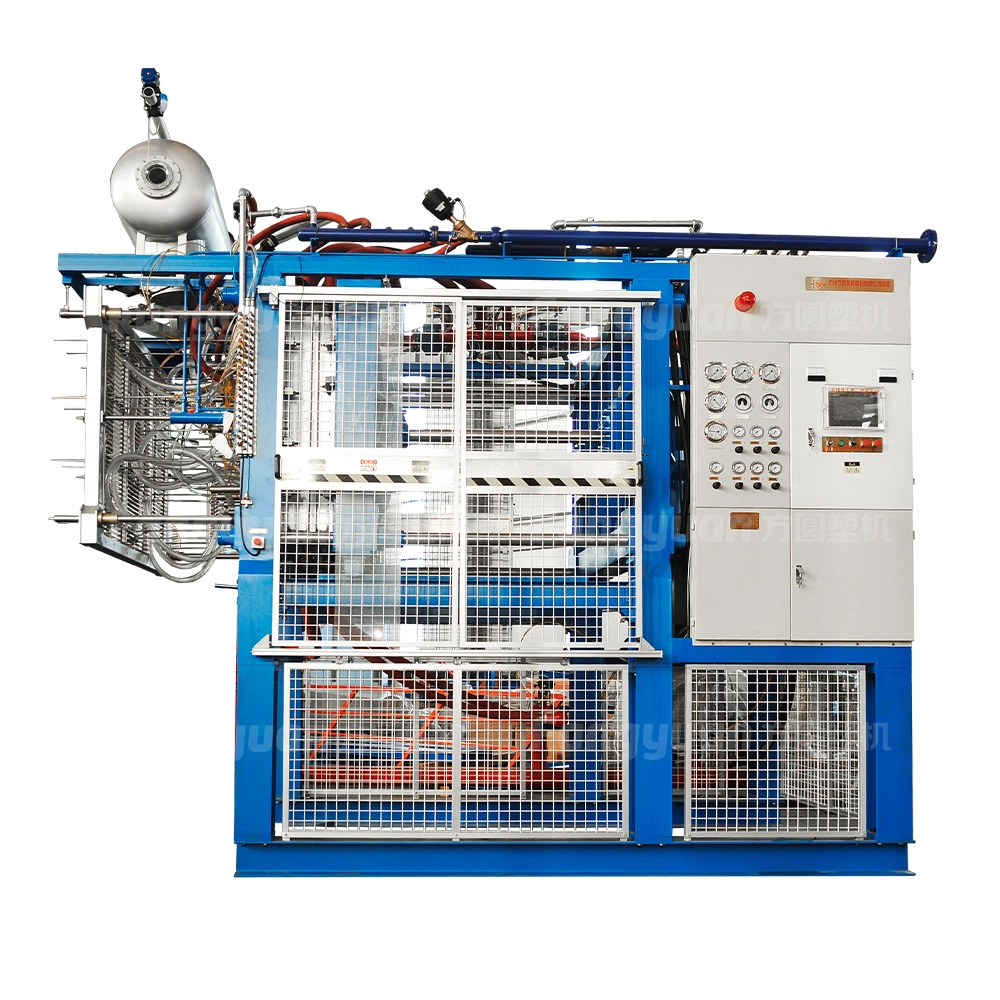

SPJ70/110/150 Batch Pre-expander-B (Basic)

Product Overview

The SPJ70/110/150 Batch Pre-expander-B (Basic) is a compact and reliable EPS foaming machine tailored for businesses seeking a cost-effective solution without compromising on quality. Despite its smaller scale compared to larger pre-expansion systems, this machine offers robust features that enhance production efficiency and improve foaming quality. It is an ideal choice for manufacturers looking for a basic yet efficient pre-expander.

Main Features

Advanced Steam System

- Precise Steam Control: Equipped with a steam pressure reducer and angle valve, the machine ensures stable operation by precisely controlling steam input. This leads to high-quality foaming beads with consistent expansion.

Electronic Filling System

- High-Precision Weighing: The electronic weighing system allows operators to set the desired filling weight via a touchscreen interface, enabling automatic material filling with high precision. This feature minimizes human error and streamlines production processes.

Efficient Material Level Control

- Photo Sensor Monitoring: A photo sensor monitors and controls the expansion level of materials during the foaming process. This ensures uniformity across all batches, minimizing waste and maximizing production output.

Automated Electrical Control

- PLC and Touchscreen Interface: Controlled by a PLC system with a user-friendly touchscreen interface, the machine supports fully automated operation. This reduces manual intervention, enhancing stability and reliability.

Optional Features

- Vibration Level Sensor: Provides more precise control over material expansion, ensuring better density consistency in the final product.

- Proportional Valves for Steam and Compressed Air: Offer fine-tuned control over steam and compressed air, optimizing performance and reducing energy consumption.

- Chamber Pressure and Temperature Sensors: Ensure precise management of both pressure and temperature during the expansion process, contributing to higher-quality foam production.

- PID Control System: For the SPJ70B model, when expansion density exceeds 30g/l, a PID control system is required to maintain accurate foam density.

Key Benefits

- Compact and Cost-Effective: Designed for businesses seeking an affordable and space-saving solution without sacrificing essential features.

- High Efficiency and Consistency: Advanced steam and automatic filling systems ensure high production efficiency and consistent foam quality.

- User-Friendly Operation: Simplified by the PLC control system and touchscreen interface, making it easy for operators to manage the foaming process with minimal training.

- Energy-Saving Design: Precise steam and material control systems reduce energy consumption and material waste, leading to lower operational costs.

Applications

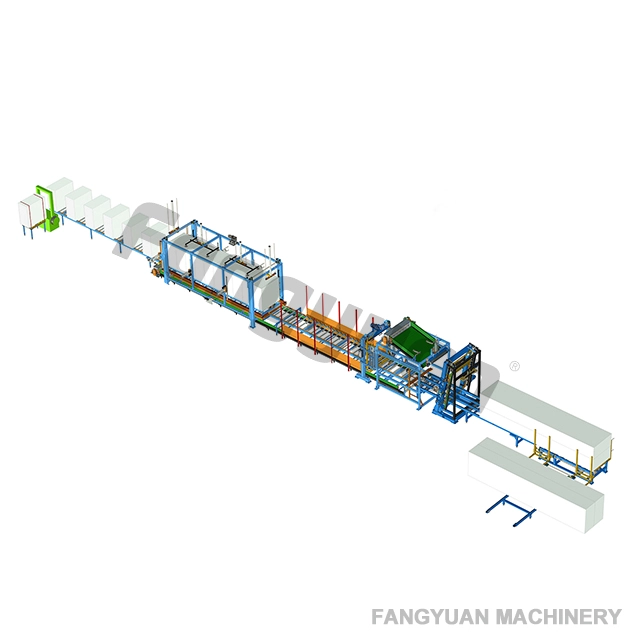

This machinery finds application in various sectors:

- Construction: Producing insulation panels for walls, roofs, and floors.

- Packaging: Manufacturing protective packaging for electronics, appliances, and fragile items.

- Agriculture: Creating lightweight containers for seedling cultivation and crop protection.

- Custom Products: Tailoring EPS blocks to meet specific project requirements.

Technical Support and Service

We provide comprehensive support services, including initial consultation, installation guidance, operator training, and ongoing after-sales service, ensuring your investment yields maximum benefits.

Case Studies

Explore real-world success stories where the SPJ70/110/150 has played a pivotal role in achieving cost reductions, waste minimization, and productivity improvements. Customer testimonials highlight the reliability and effectiveness of our solutions.

Future Directions

As technology advances, we remain committed to continuously refining our machines, introducing innovations such as enhanced automation, smarter diagnostics, and more sustainable features to stay ahead of industry trends.

Conclusion

The SPJ70/110/150 Batch Pre-expander-B (Basic) is an excellent choice for businesses looking for a reliable, cost-effective, and compact machine to expand EPS material. Designed to provide consistent performance, improve foaming quality, and streamline the production process, it delivers outstanding value and efficiency for companies seeking a simple, straightforward pre-expansion system.

For more details or to request a customized quote, contact us today!

QQ

QQ