An Advanced Solution for EPS Processing

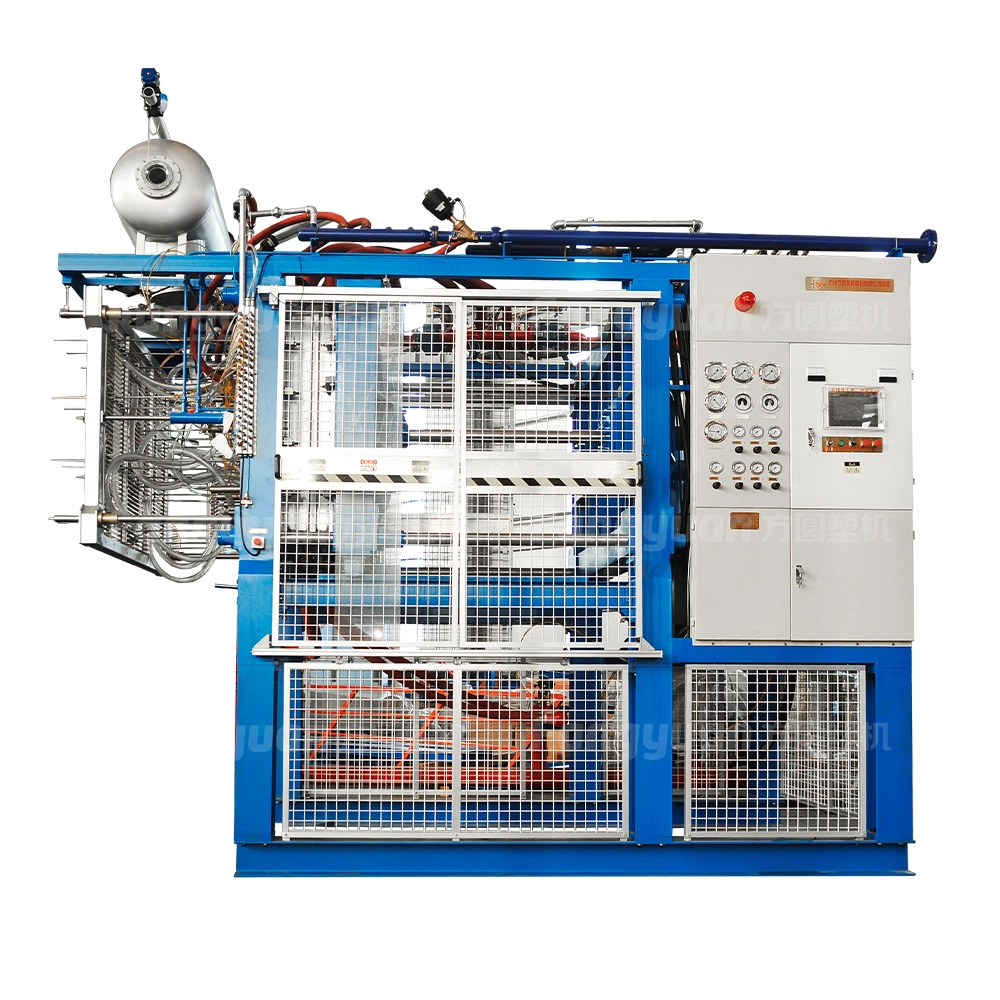

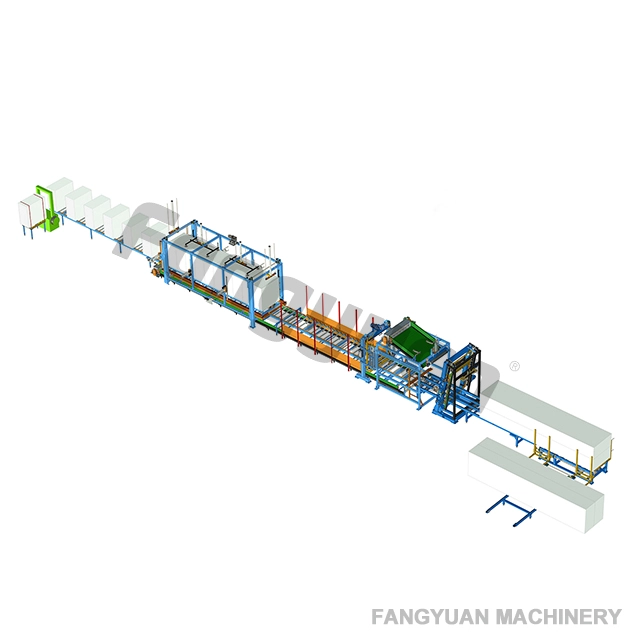

The Accuracy Batch Polystyrene Pre-expander Machine represents the pinnacle of innovation in energy-efficient technology, specifically tailored for expanding Expanded Polystyrene (EPS). This versatile equipment addresses a broad spectrum of thermoplastic foam processing needs, suitable for both expansive industrial operations and smaller-scale enterprises. Its design emphasizes minimizing material costs while maximizing energy savings, delivering exceptional performance and precision with every batch processed.

Highlighted Features

Superior Build Quality

Constructed from top-tier materials, this machine features a stainless steel dryer bed that offers outstanding corrosion resistance, ensuring a stable and hygienic drying environment. The screw conveyor, engineered with helical flights and a variable speed drive, ensures smooth and controlled material transfer. The filling system includes advanced valves and an accurate dosing mechanism, complemented by a sieving device that filters out impurities to maintain product integrity.

Accurate Steam Management

The steam system is designed with precision in mind, incorporating a pressure reducer and PID control system to maintain consistent steam flow essential for uniform EPS expansion. Fine-tuned adjustments to steam pressure create optimal conditions for producing high-quality, homogeneous material.

Efficient Pressure Regulation

Integrated pressure sensors monitor internal chamber pressure, working alongside a multi-steam exhaust system to efficiently expel excess steam. This maintains a stable pressure environment, reduces steam consumption, and enhances energy efficiency.

Advanced Temperature Management

Equipped with temperature sensors and a compressed air proportional valve, the machine provides precise control over the expansion temperature. This is crucial for maintaining product consistency and conserving heat energy during the expansion process.

Precise Material Level Monitoring

Vibrating level sensors and weighing scales offer real-time monitoring of material levels, ensuring consistent material flow and uniform expansion across all batches.

Automated Filling System

A user-friendly touchscreen interface allows operators to easily set desired filling weights, automating the process to eliminate human error and improve production efficiency.

Dependable Electrical Controls

Featuring a PLC touch screen and components from globally renowned brands, the machine ensures reliable operation, simplifying the control process and optimizing production.

Optional Enhancements

Auto Density-Weighing System: Ensures consistent foam density throughout the expansion process.

Secondary Expansion Device: Improves foam quality and expands capacity, ideal for applications requiring enhanced insulation or lightweight products.

Core Advantages

Energy Efficiency: Precise regulation of steam and heat usage significantly reduces consumption.

Cost Savings on Materials: Minimizes waste and optimizes raw material use.

Consistent Product Output: Ensures uniform foam expansion and decreases defective products.

Automation: Streamlines production processes and frees up personnel for other tasks.

Summary

For manufacturers aiming to elevate their EPS production with precision, efficiency, and reliability, the Accuracy Batch Polystyrene Pre-expander Machine presents a robust and cost-effective solution. It sets a new benchmark in high-performance engineering, offering unparalleled control and automated features for superior foam production. To learn more about this machine or to request a quote, please contact us today.

QQ

QQ