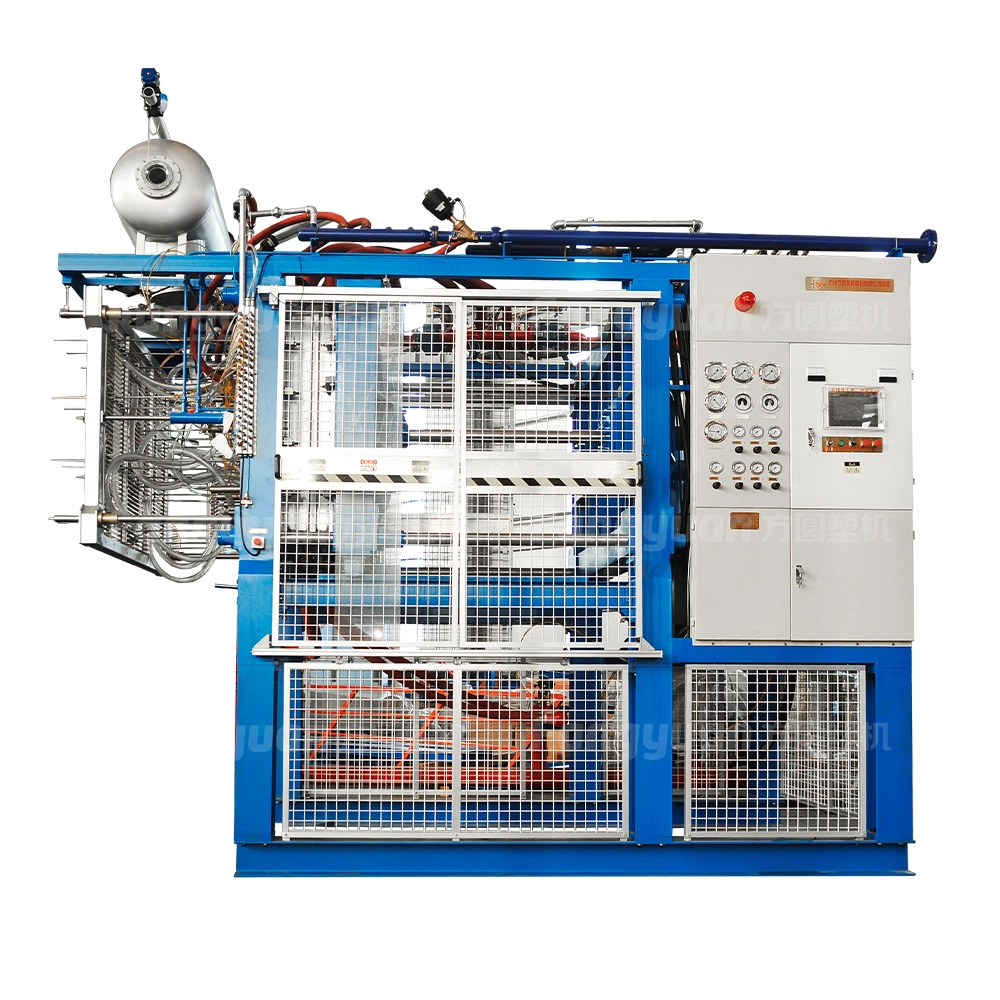

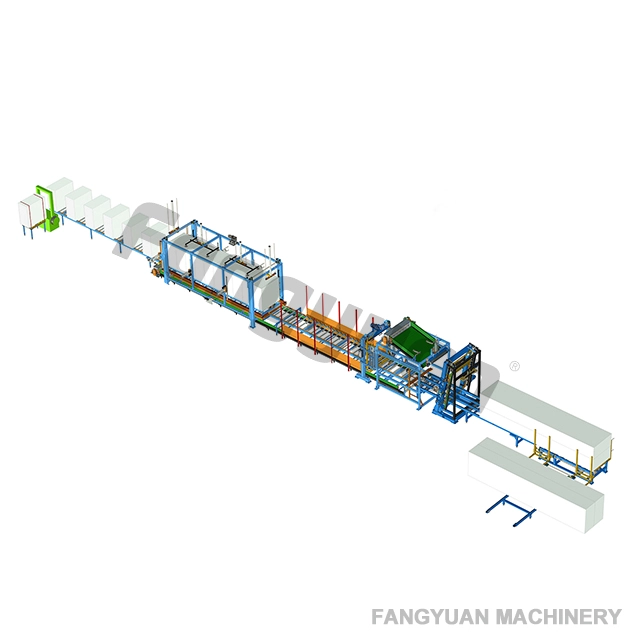

Automatic Vacuum EPS Expandable Polystyrene Beads Foaming Pre-expander Machine

Product Overview

The Automatic Vacuum EPS Expandable Polystyrene Beads Foaming Pre-expander Machine represents a revolutionary leap in the domain of EPS foam production. It is a state-of-the-art solution that combines innovative engineering with advanced technological features to offer an unprecedented level of efficiency and consistency. At its core, the incorporation of a vacuum drying system sets it apart, endowing it with the ability to meticulously manage the foaming process. This results in not only a remarkable reduction in energy consumption but also a significant enhancement of the overall production efficiency.

Main Features

- Intelligent Computer Control System

The machine is furnished with a highly sophisticated intelligent computer control system, which is designed with a remarkably user-friendly interface. This interface serves as a gateway for operators to effortlessly manage and optimize the production process. It offers the unique functionality of storing and retrieving feeding formulas, thereby streamlining process control and eliminating the need for repetitive manual adjustments. Moreover, the system's ability to meticulously track the pre-foaming process in real-time provides invaluable insights and data for quality assurance and process optimization. The support for remote updates further augments its flexibility, allowing for seamless adaptation to evolving production requirements. Additionally, the seamless interconnection between machines enabled by this system fosters a highly automated and coordinated production environment, enhancing overall operational flexibility and productivity. - Precise Manual Closed-Loop System

The machine is equipped with a manual intellectual closed-loop control system that exhibits exceptional performance characteristics. It facilitates rapid heating and pressurization within the cylinder, ensuring a swift and efficient foaming process. During operation, this system demonstrates remarkable linearity and minimal fluctuations, which are essential for achieving a consistently high-quality foam output. This level of precision and stability directly translates into a significant reduction in steam consumption, with a remarkable 30% less steam required per ton of material. Such energy-efficient performance not only reduces operational costs but also aligns with the growing global emphasis on sustainable manufacturing practices. - Vacuum Drying for Faster Curing

The integration of vacuum drying technology is a game-changer in the foaming process. It effectively expedites the curing time of the EPS beads, thereby accelerating the entire foaming cycle. This enhanced speed of material turnover has a profound impact on overall productivity, as it allows for a more rapid production throughput. Additionally, the reduced molding duration for products means that manufacturers can meet market demands more efficiently and at a lower operational cost. The vacuum drying system operates by creating a controlled low-pressure environment that promotes the rapid removal of moisture and other volatile substances from the EPS beads, ensuring a more stable and consistent foaming process. - Precise Raw Material Weighing System

The machine features a highly accurate raw material weighing system that incorporates density-based weighing and self-adjusting capabilities. This advanced system is designed to ensure the precise input of raw materials, which is crucial for maintaining consistent foam density. By accurately measuring and adjusting the amount of material based on density requirements, the machine is able to produce foam with uniform quality characteristics. This not only meets but exceeds the high-quality standards demanded by the industry, ensuring that each batch of foam produced is of the highest caliber and suitable for a wide range of applications. - Premium Components for Reliable Performance

To guarantee long-term reliability and uninterrupted operation, the machine is constructed using top-of-the-line components sourced from globally renowned brands. Every key part, including valves, electrical components, and other critical elements, is carefully selected for its outstanding stability and durability. These high-quality components work in harmony to ensure that the machine operates smoothly and consistently, minimizing the risk of breakdowns and unforeseen downtime. This reliability is essential for maintaining a steady production schedule and meeting customer demands in a timely and efficient manner.

Why Choose Our EPS Pre-expander Machine?

- Energy-Efficient

The unique combination of the vacuum drying system and the advanced closed-loop control mechanism results in a remarkable 30% reduction in steam consumption. This significant energy savings not only translates into lower operational costs but also contributes to a more sustainable manufacturing process. By optimizing energy usage, manufacturers can enhance their competitiveness while also fulfilling their environmental responsibilities. - Faster Production

The vacuum drying technology's ability to shorten curing times has a direct and positive impact on production speed. It accelerates the material turnover rate, allowing for a more rapid production cycle. This means that manufacturers can produce more EPS foam in a shorter period, meeting market demands more effectively and increasing overall productivity. The reduced molding duration also enables faster delivery times, enhancing customer satisfaction and market responsiveness. - Accurate Control

The precise weighing and density feedback system incorporated into the machine ensures that foam quality remains consistent across all production batches. This level of accuracy is essential for applications where strict quality control is required, such as in the construction and packaging industries. By maintaining a uniform foam density, the machine produces a reliable and high-performing product that meets the specific needs of each application. - User-Friendly Operation

The intelligent computer control system simplifies the operation of the machine to a great extent. Its user-friendly interface allows operators to easily customize settings according to their production requirements. The ability to store and recall feeding formulas further streamlines the process, reducing the potential for human error. Additionally, the support for remote updates ensures that the machine can adapt to new production techniques and requirements without significant downtime or disruption. - Reliable Performance

The use of premium components sourced from reputable brands is the cornerstone of the machine's reliable performance. These components are known for their durability and stability, ensuring that the machine operates smoothly and consistently over an extended period. The minimized risk of breakdowns and downtime means that manufacturers can rely on the machine to meet production schedules and maintain a high level of productivity.

Conclusion

The Automatic Vacuum EPS Expandable Polystyrene Beads Foaming Pre-expander Machine is a high-performance, energy-efficient solution that is ideally suited for manufacturers aiming to optimize their EPS foam production processes. Its advanced vacuum drying technology, precise control systems, and energy-saving features combine to enhance both the quality and speed of production.

QQ

QQ