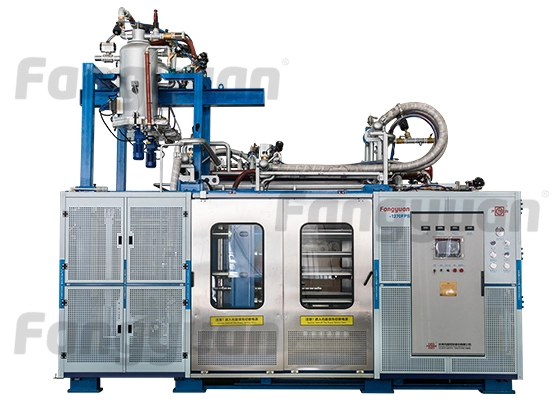

FPS Series Fast Mold Change System EPP Molding Machine for Automotive Parts

Product Overview

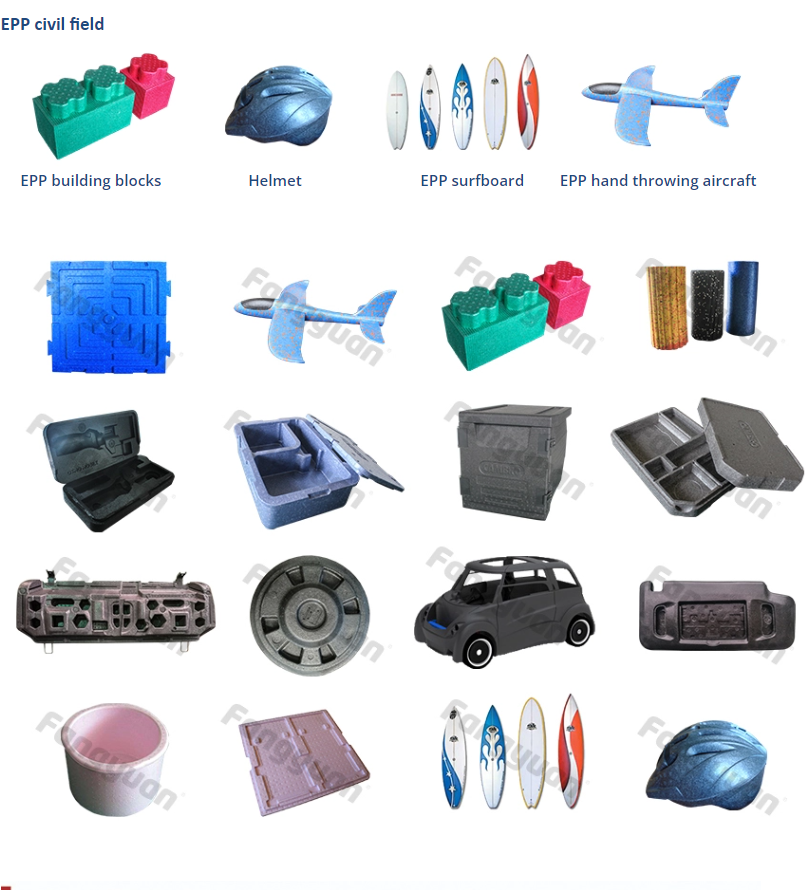

The FPS Series EPP Molding Machine is an advanced, high-performance solution specifically designed for the production of Expanded Polypropylene (EPP) car parts. With its fast mold change system, precise control over material processing, and robust design, this machine delivers both efficiency and versatility for automotive manufacturers. Ideal for producing lightweight, durable, and energy-absorbing automotive components, the FPS Series enhances production flexibility while ensuring top-quality results.

Key Features

-

Versatile Feeding Methods

The machine supports multiple feeding methods to ensure optimal material flow and consistency, including:- Pulse Feeding

- Negative Pressure Feeding

- Back Pressure Feeding

- Wind-Assisted Feeding

These varied feeding methods offer flexibility to accommodate different production requirements and material characteristics.

-

High-Precision Smart Proportional Valves

Equipped with high-precision smart proportional valves, the machine provides accurate control over key processes, including feeding, heating, and mold unloading. This ensures optimal material flow and uniform molding, contributing to consistent product quality. -

Integrated Hydraulic Power System

The machine features an intensive hydraulic power system that integrates both powering and pressurization functions. This integration simplifies maintenance and improves operational efficiency, allowing for consistent and stable performance even during extended production runs. -

Fast Mold Change System

The Fast Mold Change System is designed to significantly reduce downtime by enabling quick and efficient mold swaps. This feature enhances production flexibility, allowing manufacturers to rapidly switch between different molds for various automotive parts, improving overall productivity and minimizing idle time. -

Self-Equipped Water Tank (Steam Chest)

The machine comes with a self-equipped water tank (steam chest) for optimal cooling and temperature regulation during the molding process. This feature ensures consistent heating and prevents overheating, improving the quality of the molded products. -

Precise Joint Retention Accuracy

The machine guarantees precise joint retention with an accuracy margin of less than 0.5mm, ensuring that each EPP car part is molded to exact specifications. This high level of precision results in superior product quality and performance. -

High-Rigidity Frame for Long-Term Durability

Built with high-rigidity frames, the machine is designed to withstand the demands of continuous production in the EPP industry. The robust frame ensures long-lasting durability, stable performance, and minimal maintenance requirements over time. -

Comprehensive Safety Features

The FPS Series Molding Machine is equipped with multiple safety devices to ensure the protection of operators and reduce the risk of accidents. These safety features include emergency stop buttons, protective covers, and safeguards for moving parts.

How It Works

The FPS Series EPP Molding Machine uses a combination of advanced heating systems and high-precision feeding methods to expand and mold EPP material into automotive parts. The integrated hydraulic system ensures stable pressurization, while the smart proportional valves regulate the flow of material and temperature. The fast mold change system allows for efficient mold swapping, while the self-equipped water tank (steam chest) ensures consistent temperature control during molding.

Why Choose Our FPS Series EPP Molding Machine?

- Flexibility: The fast mold change system allows for rapid switching between different molds, enhancing production flexibility and efficiency.

- Precision: High-precision valves and accurate joint retention guarantee that every molded automotive part meets the required specifications with consistency.

- Durability: The high-rigidity frame ensures long-term performance, even under continuous use in demanding production environments.

- Efficiency: Multiple feeding methods and an integrated hydraulic system ensure smooth, high-efficiency production cycles.

- Safety: Built-in safety features provide a secure working environment, reducing the risk of accidents and protecting operators.

- Maintenance-Friendly: The intensive hydraulic system and self-equipped water tank make maintenance easier and reduce downtime, keeping your production line running smoothly.

Conclusion

The FPS Series Fast Mold Change System EPP Molding Machine is a cutting-edge solution for the production of EPP car parts. With its fast mold change capability, high-precision control systems, and durable construction, this machine enhances manufacturing efficiency while ensuring the production of high-quality automotive components. Invest in the FPS Series EPP Molding Machine to improve your production capacity, reduce downtime, and meet the increasing demand for high-performance EPP automotive parts.

QQ

QQ