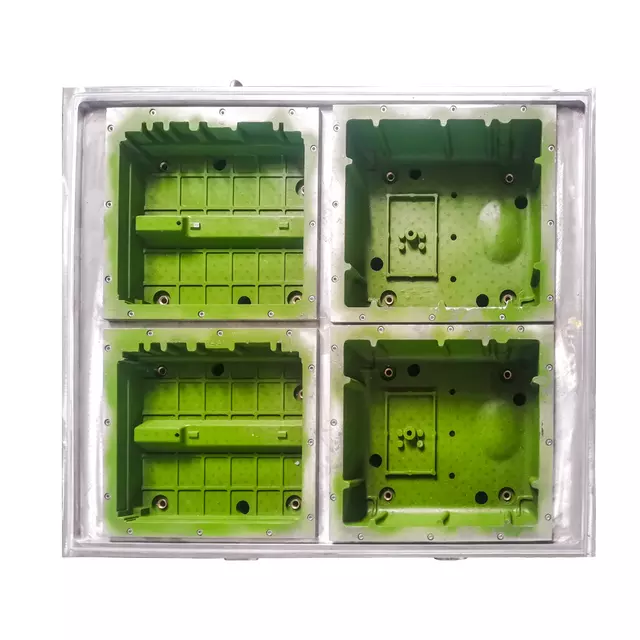

Customized EPS Moulds for Vegetable and Fruit Boxes

Product Overview

Fangyuan's EPS Mould Division stands as a preeminent provider in the realm of customized EPS moulds, with a particular specialization in the production of vegetable and fruit boxes. Bolstered by a proficient team comprising over 100 individuals, among which more than 20 are highly seasoned engineers and technicians, we harness the power of cutting-edge technologies such as CAD, UG, PRO/E, CAM programming, and AutoCAD/2000 to offer precision-engineered moulding solutions. Our unwavering dedication to quality assurance dictates that each and every mould is meticulously crafted to precisely meet the stringent requirements of the packaging industry, thereby furnishing reliable and efficient solutions for a diverse array of applications.

Constructed from top-tier 6063 aluminum alloy and integrated with the latest technological advancements, our EPS moulds are engineered to manifest durability, precision, and cost-effective production. Specifically customized for the manufacturing of vegetable and fruit boxes, our moulds underpin sustainable and streamlined packaging solutions.

Key Features of EPS Moulds for Vegetable and Fruit Boxes

- Premium Aluminum Alloy Construction

Our EPS moulds are fabricated from high-grade 6063 aluminum alloy, endowing them with remarkable strength, durability, and resistance to wear. This empowers the moulds to endure the rigors of intensive production cycles, consistently delivering sterling performance and an extended service life. - Advanced Design and Precision Manufacturing

We capitalize on advanced design software like CAD, UG, and PRO/E for the creation of elaborate mould designs, while CAM programming and AutoCAD/2000 facilitate exacting manufacturing processes. These technological assets ensure the attainment of the utmost level of accuracy and uniformity in every mould that rolls off our production line. - Integrated Mould Chambers and Cooling Systems

Our moulds are equipped with standardized chambers and cooling systems, which are optimized to streamline the production process. These designs are engineered to ensure homogeneous cooling, thereby culminating in efficient production and unwavering quality throughout every production cycle. - Protective Teflon Coating

The surface of the mould is laminated with a Teflon layer, which augments lubrication, precludes material adhesion, and eases the demoulding process. This not only curtails maintenance requirements but also accelerates production velocity and prolongs the operational lifespan of the moulds. - Superior Heat and Corrosion Resistance

Fangyuan's EPS moulds are meticulously engineered to withstand temperatures in excess of 350°C and exhibit formidable corrosion resistance. This renders them eminently suitable for demanding production milieus, guaranteeing long-term dependability without any compromise in performance. - Longevity and Cost-Effectiveness

Fabricated using premium-grade materials and avant-garde techniques, our moulds are devised to proffer enduring performance with minimal maintenance overheads. Their high resistance to wear and tear ensures a reduction in operational downtime and enhanced cost-efficiency over the long haul. - Versatile Applications

While optimized for vegetable and fruit box production, our moulds possess a remarkable degree of versatility and adaptability to cater to a wide gamut of packaging requisites. Ranging from styrofoam packaging to food containers and other bespoke foam products, Fangyuan's moulds can be custom-tailored to satiate a diverse range of demands. - Efficient Production with Minimal Waste

Our mould designs are contrived to ensure efficient utilization of materials and rapid cycle times, thereby diminishing production waste and augmenting yield. Complemented by the Teflon coating for seamless demoulding, these moulds enable high-velocity production runs, maximizing overall productivity.

Why Choose Fangyuan EPS Moulds?

Fangyuan's customized EPS moulds amalgamate robust construction, advanced technology, and peerless efficiency to address the ever-evolving exigencies of the packaging industry.

Durable Design: The utilization of high-quality 6063 aluminum alloy vouchsafes long-term durability and sterling performance.

Precision Engineering: State-of-the-art design and manufacturing tools ensure the production of accurate moulds for consistent and reliable outcomes.

Easy Maintenance: Attributes such as the Teflon coating simplify the demoulding process and extend the operational lifespan of the mould.

Versatility: Customizable to accommodate a diverse range of packaging applications beyond the purview of vegetable and fruit boxes.

Sustainability: Efficient designs curtail waste, ensuring cost-effective and environmentally friendly production.

Conclusion

Fangyuan's customized EPS moulds for vegetable and fruit boxes epitomize a seamless fusion of quality, durability, and cost-efficiency. With our advanced design capabilities and precision manufacturing processes, our moulds play a pivotal role in streamlining production, curtailing costs, and yielding exceptional results.

Contact us today to discover how Fangyuan's EPS mould solutions can supercharge your production efficiency and furnish sustainable, high-performance packaging alternatives for your business.

Premium Aluminum Alloy Construction

Our EPS moulds are fabricated from high-grade 6063 aluminum alloy, endowing them with remarkable strength, durability, and resistance to wear. This empowers the moulds to endure the rigors of intensive production cycles, consistently delivering sterling performance and an extended service life.

Our EPS moulds are fabricated from high-grade 6063 aluminum alloy, endowing them with remarkable strength, durability, and resistance to wear. This empowers the moulds to endure the rigors of intensive production cycles, consistently delivering sterling performance and an extended service life.

Advanced Design and Precision Manufacturing

We capitalize on advanced design software like CAD, UG, and PRO/E for the creation of elaborate mould designs, while CAM programming and AutoCAD/2000 facilitate exacting manufacturing processes. These technological assets ensure the attainment of the utmost level of accuracy and uniformity in every mould that rolls off our production line.

We capitalize on advanced design software like CAD, UG, and PRO/E for the creation of elaborate mould designs, while CAM programming and AutoCAD/2000 facilitate exacting manufacturing processes. These technological assets ensure the attainment of the utmost level of accuracy and uniformity in every mould that rolls off our production line.

Integrated Mould Chambers and Cooling Systems

Our moulds are equipped with standardized chambers and cooling systems, which are optimized to streamline the production process. These designs are engineered to ensure homogeneous cooling, thereby culminating in efficient production and unwavering quality throughout every production cycle.

Our moulds are equipped with standardized chambers and cooling systems, which are optimized to streamline the production process. These designs are engineered to ensure homogeneous cooling, thereby culminating in efficient production and unwavering quality throughout every production cycle.

Protective Teflon Coating

The surface of the mould is laminated with a Teflon layer, which augments lubrication, precludes material adhesion, and eases the demoulding process. This not only curtails maintenance requirements but also accelerates production velocity and prolongs the operational lifespan of the moulds.

The surface of the mould is laminated with a Teflon layer, which augments lubrication, precludes material adhesion, and eases the demoulding process. This not only curtails maintenance requirements but also accelerates production velocity and prolongs the operational lifespan of the moulds.

Superior Heat and Corrosion Resistance

Fangyuan's EPS moulds are meticulously engineered to withstand temperatures in excess of 350°C and exhibit formidable corrosion resistance. This renders them eminently suitable for demanding production milieus, guaranteeing long-term dependability without any compromise in performance.

Fangyuan's EPS moulds are meticulously engineered to withstand temperatures in excess of 350°C and exhibit formidable corrosion resistance. This renders them eminently suitable for demanding production milieus, guaranteeing long-term dependability without any compromise in performance.

Longevity and Cost-Effectiveness

Fabricated using premium-grade materials and avant-garde techniques, our moulds are devised to proffer enduring performance with minimal maintenance overheads. Their high resistance to wear and tear ensures a reduction in operational downtime and enhanced cost-efficiency over the long haul.

Fabricated using premium-grade materials and avant-garde techniques, our moulds are devised to proffer enduring performance with minimal maintenance overheads. Their high resistance to wear and tear ensures a reduction in operational downtime and enhanced cost-efficiency over the long haul.

Versatile Applications

While optimized for vegetable and fruit box production, our moulds possess a remarkable degree of versatility and adaptability to cater to a wide gamut of packaging requisites. Ranging from styrofoam packaging to food containers and other bespoke foam products, Fangyuan's moulds can be custom-tailored to satiate a diverse range of demands.

While optimized for vegetable and fruit box production, our moulds possess a remarkable degree of versatility and adaptability to cater to a wide gamut of packaging requisites. Ranging from styrofoam packaging to food containers and other bespoke foam products, Fangyuan's moulds can be custom-tailored to satiate a diverse range of demands.

Efficient Production with Minimal Waste

Our mould designs are contrived to ensure efficient utilization of materials and rapid cycle times, thereby diminishing production waste and augmenting yield. Complemented by the Teflon coating for seamless demoulding, these moulds enable high-velocity production runs, maximizing overall productivity.

Our mould designs are contrived to ensure efficient utilization of materials and rapid cycle times, thereby diminishing production waste and augmenting yield. Complemented by the Teflon coating for seamless demoulding, these moulds enable high-velocity production runs, maximizing overall productivity.

Precision Engineering: State-of-the-art design and manufacturing tools ensure the production of accurate moulds for consistent and reliable outcomes.

Easy Maintenance: Attributes such as the Teflon coating simplify the demoulding process and extend the operational lifespan of the mould.

Versatility: Customizable to accommodate a diverse range of packaging applications beyond the purview of vegetable and fruit boxes.

Sustainability: Efficient designs curtail waste, ensuring cost-effective and environmentally friendly production.

QQ

QQ