Fangyuan EPS/EPP Moulding Machines

Company Overview

Fangyuan Mould Branch is a market leader in the design and production of high-quality EPS and EPP moulds, catering to diverse foam moulding needs. Backed by a team of over 100 skilled professionals, including more than 20 experienced engineers and technicians, we utilize cutting-edge technologies such as CAD, UG, PRO/E, CAM programming, and AutoCAD/2000. With 10 state-of-the-art CNC machining centers and nearly 30 general mould machining tools, we deliver precision-engineered EPS moulding solutions designed for superior performance and reliability.

Specializing in EPS, EPP, and thermocol moulds, we craft moulding solutions that meet the demands of various industries. Using 6063 premium-grade aluminum alloy, our moulds are renowned for their exceptional durability, precision, and ability to deliver consistent, long-term results.

Key Features of Fangyuan EPS/EPP Moulds

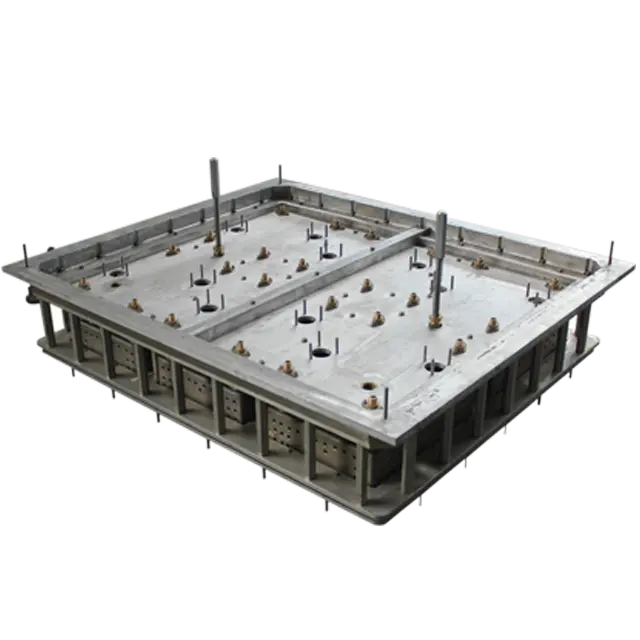

1. Premium Aluminum Alloy Construction

Fangyuan’s moulds are made from 6063 aluminum alloy, known for its excellent strength, wear resistance, and durability. This high-quality material ensures that our moulds perform reliably, even under continuous, high-volume production conditions.

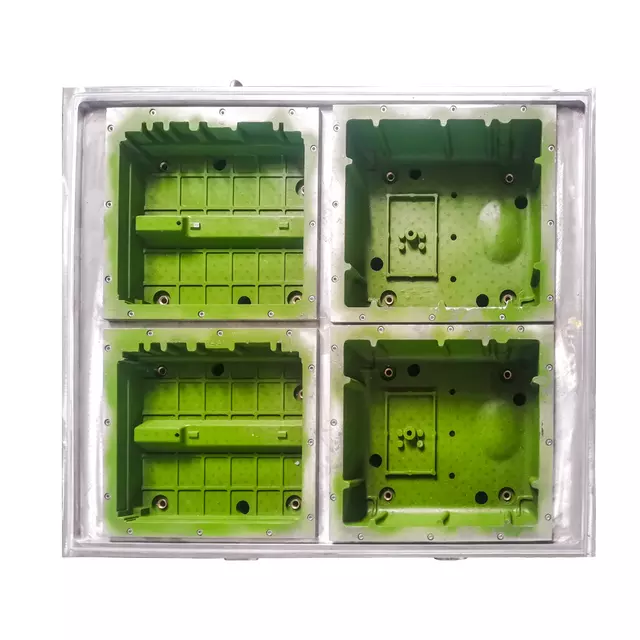

2. Precision Design and Advanced Manufacturing

By utilizing advanced design tools like CAD, UG, and PRO/E, and employing CAM programming for production, our moulds achieve unparalleled precision. This meticulous approach ensures every mould meets the highest industry standards, delivering consistent results cycle after cycle.

3. Integrated Cooling Systems

Our moulds feature built-in standard cooling systems that ensure uniform cooling for efficient production. This optimized design reduces cycle times, enhances productivity, and maintains the superior quality of the finished product.

4. Teflon Coating for Seamless Operation

The moulds are treated with a protective Teflon coating to enhance performance. This coating minimizes material adhesion, making de-moulding quicker and smoother. It also reduces maintenance needs and extends the lifespan of the moulds, ensuring high efficiency and reliability.

5. Resistance to High Temperatures and Corrosion

Fangyuan moulds are designed to withstand extreme conditions, including temperatures exceeding 350°C. The moulds also exhibit exceptional resistance to corrosion, making them suitable for long-term use in demanding production environments while maintaining consistent performance.

6. Durability for Long-Term Use

The combination of premium 6063 aluminum alloy and precision manufacturing techniques ensures that our moulds are highly durable and capable of withstanding rigorous production requirements. Their extended lifespan and low maintenance needs help reduce overall production costs.

7. Versatility Across Applications

Our EPS and EPP moulds are suitable for a wide range of applications, including styrofoam packaging, foam boxes, and custom foam products. Whether for standard moulds or retractable designs, Fangyuan provides tailored solutions to meet the unique requirements of your production process.

8. Efficient Production and Minimal Downtime

Fangyuan’s moulds are designed for optimal efficiency, featuring easy-to-demould capabilities and low-maintenance requirements. These features minimize downtime, increase production speed, and help maintain a high yield, reducing operational costs.

Why Choose Fangyuan EPS/EPP Moulding Machines?

- Superior Materials: Crafted from premium 6063 aluminum alloy for unmatched durability and reliability.

- Advanced Technology: Designed using the latest CAD and CAM tools for precise and consistent results.

- Low Maintenance: Teflon coating ensures easy de-moulding and minimizes upkeep, maximizing uptime.

- Tailored Solutions: Customizable moulds to suit a variety of applications, from packaging to foam products.

- Cost-Efficiency: Built to last, our moulds deliver high-quality results with reduced operational costs.

Conclusion

Fangyuan’s EPS and EPP moulding machines are a perfect combination of innovation, quality, and efficiency. Featuring robust construction, advanced design, and reliable performance, our moulds are built to deliver outstanding results across diverse foam moulding applications. Whether producing EPS foam boxes, styrofoam packaging, or custom foam products, Fangyuan offers durable, efficient, and customizable moulding solutions to meet your production needs.

QQ

QQ