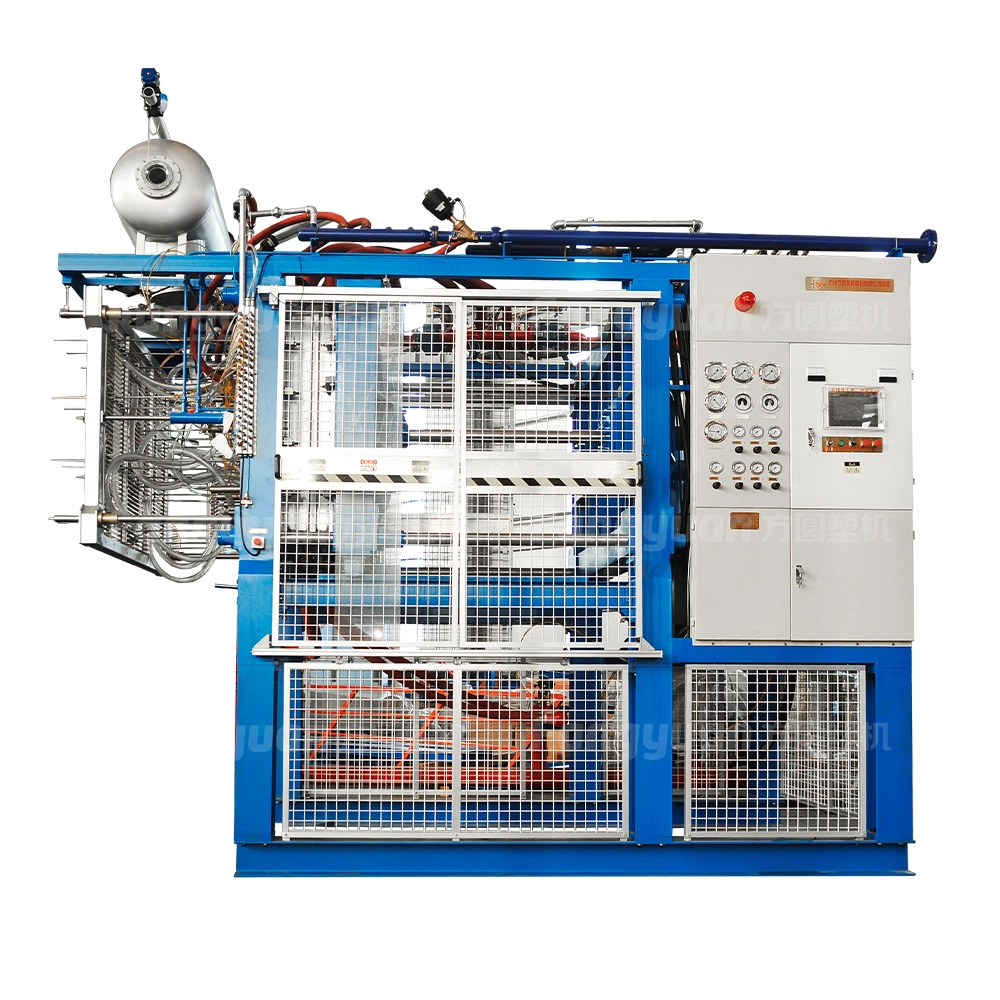

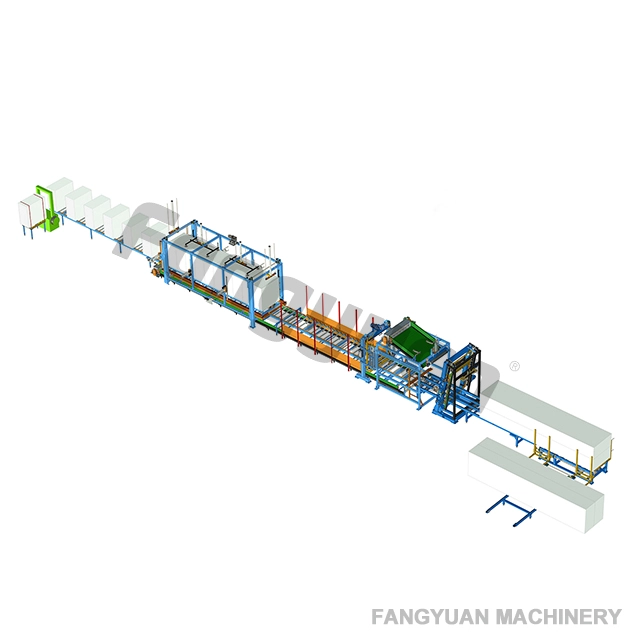

Polystyrene Molding Machine with Vacuum for EPS Box

The Polystyrene Molding Machine is designed for efficient production of EPS (Expandable Polystyrene) boxes, with numerous improvements over basic molding machines. Below are the key features of this advanced EPS molding machine:

Main Features

1. Robust Machine Structure

- High-Strength Frame Design:

- The machine frame is welded onto a 16/20mm steel plate, ensuring enhanced strength and durability for reliable operation.

- Stable High Legs:

- The machine is equipped with sturdy “H” type profile high legs, providing easy installation by simply preparing a floor foundation.

2. Advanced Filling System

- Normal Pressure and Vacuum Filling:

- The system utilizes both normal pressure and vacuum for high-pressurized filling, ensuring efficient material filling.

- Level Sensor Control:

- Material filling is controlled by a level sensor with double rotation chamber discharge and 44 filling outlets, ensuring accuracy and consistency.

3. Optimized Steam System

- PID Control Valve with German Gauge:

- A balance PID control valve and a German gauge improve steam pressure accuracy, resulting in a 20% reduction in steam consumption compared to A/B type EPS molding machines.

- Energy Efficiency:

- This system helps optimize steam usage, reducing overall energy costs and improving production efficiency.

4. Efficient Cooling System

- Vacuum Cooling:

- The machine is equipped with a large vacuum pump and vertical tank, complemented by a vertical vacuum cooling water spray system.

- Vacuum cooling is used as the primary cooling method, reducing water content in the product to less than 10%. This is more energy-efficient than traditional water cooling systems, which typically operate for only 8-12 seconds.

5. Enhanced Drainage System

- Improved Inlet and Outlet Sizes:

- The system features a large 8-1” steam inlet, ensuring quick cycle times.

- The drainage system includes 6/8-2” outlets and a 6” large drainage pipe controlled by a butterfly valve, significantly improving the heating and drainage speed of the EPS molding machine.

6. Advanced Control System

- User-Friendly Interface:

- The machine uses a PLC (Mitsubishi) and a Schneider touch screen for easy operation, ensuring that even complex processes can be managed smoothly.

- Stable Performance:

- All electronic components are sourced from renowned brands, which greatly improve the machine's stability and reliability.

- Comprehensive Control:

- The system controls air cooling, steam, de-molding, and pressure filling with long-distance balance valves, ensuring precise and efficient operation.

Conclusion

The Polystyrene Molding Machine with Vacuum for EPS Box is an advanced solution for producing high-quality EPS boxes. Its robust design, optimized filling and steam systems, efficient cooling and drainage, and advanced control features make it an excellent choice for businesses looking to increase productivity and reduce operational costs.

QQ

QQ