China Auto EPS Pre-expander Machine with Reduced Steam Consumption

Product Description

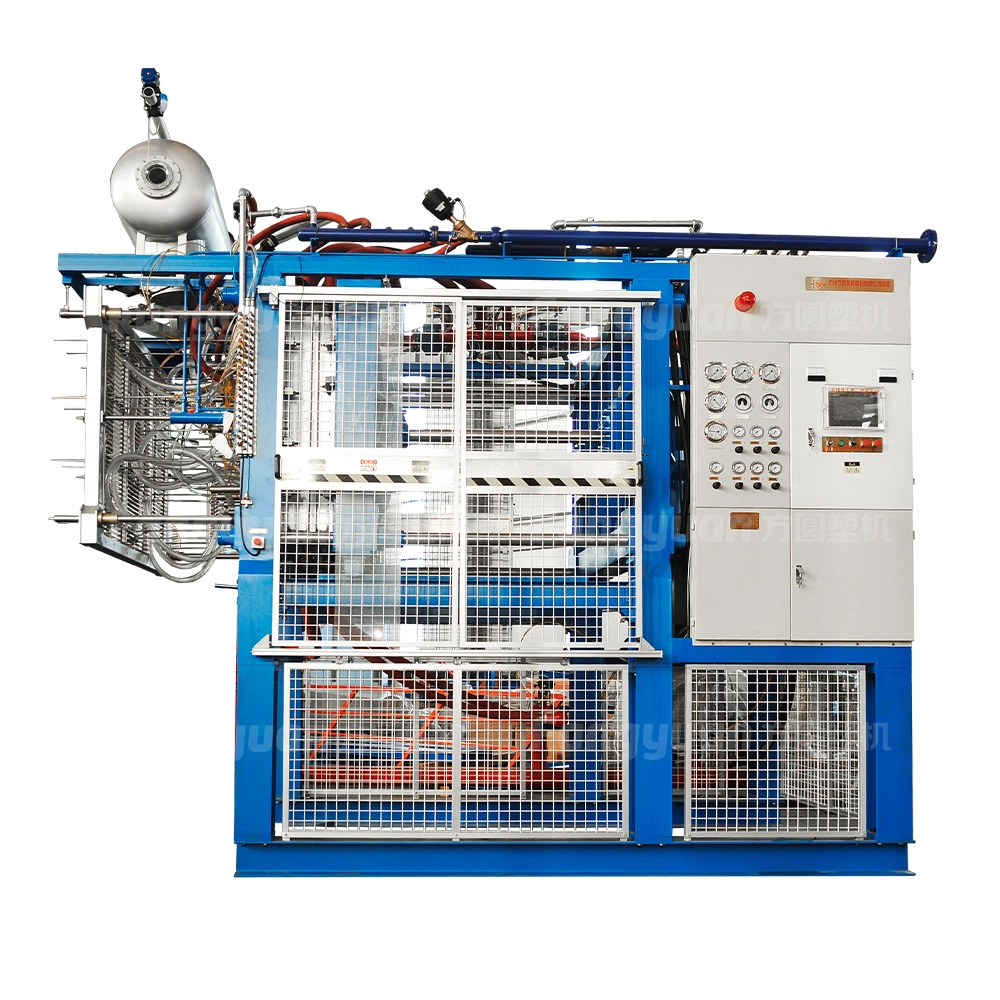

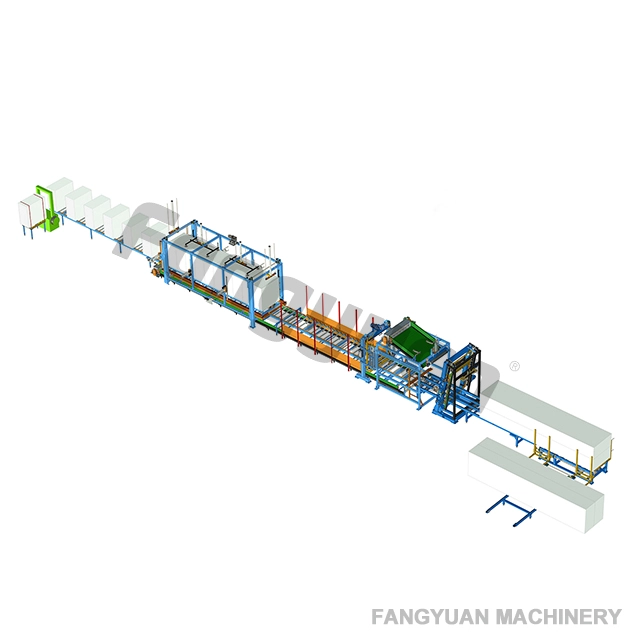

The SPJ50/90/130/160 Batch EPS Pre-expander Machine - A (Accuracy) harnesses cutting-edge technology to supercharge the production of EPS foam. Engineered for highly efficient foaming, this machine substantially augments both production efficiency and the caliber of EPS beads. It guarantees precise, lightweight, and rapid expansion, accompanied by dependable operation and a low incidence of malfunctions, all while optimizing steam consumption.

Main Features

- Complete Pre-expansion Equipment

The batch EPS pre-expander machine is furnished with a stainless steel dryer bed, screw conveyor, filling system, sieving device, and other components. The stainless steel dryer bed is crafted with top-grade stainless steel, ensuring excellent corrosion resistance and durability. The screw conveyor, with its precisely engineered helical blades and variable speed drive, transports the EPS raw material smoothly and precisely. The filling system, featuring high-precision valves and a calibrated dosing mechanism, enables accurate and consistent material introduction. The sieving device, equipped with adjustable meshes, efficiently filters out oversized or undersized particles, guaranteeing a homogeneous product. This comprehensive ensemble presents a fully integrated solution for EPS foam production. - Efficient Steam System

The machine is outfitted with an accurate pressure reducer and PID control system, along with a proportional steam valve. The pressure reducer is designed with state-of-the-art technology, allowing for minute adjustments in steam pressure. The PID control system, through its intelligent feedback loop, continuously monitors and corrects the steam pressure to maintain an unwavering level. The proportional steam valve further refines the steam flow control, ensuring that the pressure within the machine remains consistent. This results in a bead foaming error within ±2%, ensuring the uniformity and quality of the expanded beads. - Pressure Control System

The pressure sensor and multi-steam exhausting system work in tandem to maintain a stable pressure in the expansion chamber. The pressure sensor, with its high sensitivity and rapid response time, accurately measures the internal pressure. The multi-steam exhausting system, composed of multiple strategically positioned vents and valves, expels excess steam in a controlled manner, thereby reducing steam consumption. This enhanced energy efficiency is achieved without any sacrifice in the quality of the foamed product. - Precise Temperature Control

A temperature sensor and compressed air proportional valve cooperate to uphold accurate expansion temperatures, which is crucial for high-density foaming. The temperature sensor, with its advanced sensing technology and fine calibration, precisely measures the temperature within the expansion chamber. The compressed air proportional valve, in response to the sensor's feedback, adjusts the flow of cooling air to maintain the optimal temperature. Additionally, the hot air drying system accelerates the drying process, expedites aging, and shortens the production cycle. This combination leads to a reduction in broken beads and an overall improvement in product quality. - Material Level Control

The accurate weighing system and vibrating level sensor ensure meticulous material filling and consistent density. The weighing system, with its high-precision load cells and digital signal processing, measures the material weight with great accuracy. The vibrating level sensor, through its sensitive vibration detection mechanism, monitors the material level in real-time. These components work together to minimize variations caused by vibrations during operation, thereby guaranteeing a reliable expansion process and uniform product quality. - Automated Material Filling System

By setting the filling weight via the touchscreen interface, the machine can automatically and precisely fill materials according to the pre-set weight parameters. The touchscreen interface is designed with user-friendly graphics and intuitive controls, allowing operators to easily input and adjust the filling weight. The machine's internal control system then activates the filling mechanism, ensuring accurate and efficient material introduction. This automation not only improves production efficiency but also reduces the potential for human error. - Stable Electric Control

The PLC touchscreen, in conjunction with components and valves sourced from renowned brands, ensures the seamless and reliable operation of the entire machine. The PLC, with its powerful processing capabilities and flexible programming options, coordinates all aspects of the machine's functions. The touchscreen provides a convenient and visual interface for operators to monitor and control the machine. The use of high-quality components and valves from reputable manufacturers minimizes the risk of malfunctions and downtime, enhancing the long-term stability of the machine.

Notes

- Auto Density-Weighing System: This feature is available as an optional upgrade. It utilizes advanced weighing and density measurement technologies to provide real-time monitoring and control of the density of the expanded beads. This enables manufacturers to produce EPS foam with highly customized density profiles, meeting the specific requirements of various applications.

- Secondary Expansion Device: Available as an option for the SPJ130 and SPJ160 models. This device further refines the foaming process by allowing for a secondary stage of expansion. It can be used to produce EPS foam with even lower densities and more intricate cell structures, enhancing the product's insulation and cushioning properties and providing greater production flexibility.

Key Benefits

- Low Steam Consumption: The optimized steam usage not only slashes energy costs but also bolsters environmental sustainability. By precisely controlling the steam pressure and flow, the machine minimizes wasteful steam consumption, reducing the carbon footprint associated with EPS production.

- Accurate and Efficient Operation: The machine delivers consistent quality and reliable performance through its precise control over temperature, pressure, and material filling. This accuracy ensures that each batch of EPS foam meets the strictest quality standards, reducing the need for rework or rejects.

- Reduced Downtime: Automated systems and high-quality components curtail maintenance requirements and operational disruptions. The machine's self-diagnostic capabilities and reliable components enable proactive maintenance, minimizing unplanned downtime and maximizing production uptime.

- Enhanced Product Quality: Faster drying, uniform bead expansion, and fewer bead breakages culminate in superior-quality EPS foam. The combination of advanced technologies and precise control mechanisms results in a product with enhanced mechanical properties, better insulation performance, and a more aesthetically pleasing appearance.

Conclusion

The SPJ50/90/130/160 Batch EPS Pre-expander Machine - A proffers a powerful, efficient, and cost-effective solution for high-quality EPS production. With its sophisticated steam and temperature control systems, automated filling, and low energy consumption, this machine addresses the escalating demands of contemporary EPS foam manufacturers striving to optimize both production and sustainability.

For more information or to place an order, contact us today!

The batch EPS pre-expander machine is furnished with a stainless steel dryer bed, screw conveyor, filling system, sieving device, and other components. The stainless steel dryer bed is crafted with top-grade stainless steel, ensuring excellent corrosion resistance and durability. The screw conveyor, with its precisely engineered helical blades and variable speed drive, transports the EPS raw material smoothly and precisely. The filling system, featuring high-precision valves and a calibrated dosing mechanism, enables accurate and consistent material introduction. The sieving device, equipped with adjustable meshes, efficiently filters out oversized or undersized particles, guaranteeing a homogeneous product. This comprehensive ensemble presents a fully integrated solution for EPS foam production.

The machine is outfitted with an accurate pressure reducer and PID control system, along with a proportional steam valve. The pressure reducer is designed with state-of-the-art technology, allowing for minute adjustments in steam pressure. The PID control system, through its intelligent feedback loop, continuously monitors and corrects the steam pressure to maintain an unwavering level. The proportional steam valve further refines the steam flow control, ensuring that the pressure within the machine remains consistent. This results in a bead foaming error within ±2%, ensuring the uniformity and quality of the expanded beads.

The pressure sensor and multi-steam exhausting system work in tandem to maintain a stable pressure in the expansion chamber. The pressure sensor, with its high sensitivity and rapid response time, accurately measures the internal pressure. The multi-steam exhausting system, composed of multiple strategically positioned vents and valves, expels excess steam in a controlled manner, thereby reducing steam consumption. This enhanced energy efficiency is achieved without any sacrifice in the quality of the foamed product.

A temperature sensor and compressed air proportional valve cooperate to uphold accurate expansion temperatures, which is crucial for high-density foaming. The temperature sensor, with its advanced sensing technology and fine calibration, precisely measures the temperature within the expansion chamber. The compressed air proportional valve, in response to the sensor's feedback, adjusts the flow of cooling air to maintain the optimal temperature. Additionally, the hot air drying system accelerates the drying process, expedites aging, and shortens the production cycle. This combination leads to a reduction in broken beads and an overall improvement in product quality.

The accurate weighing system and vibrating level sensor ensure meticulous material filling and consistent density. The weighing system, with its high-precision load cells and digital signal processing, measures the material weight with great accuracy. The vibrating level sensor, through its sensitive vibration detection mechanism, monitors the material level in real-time. These components work together to minimize variations caused by vibrations during operation, thereby guaranteeing a reliable expansion process and uniform product quality.

By setting the filling weight via the touchscreen interface, the machine can automatically and precisely fill materials according to the pre-set weight parameters. The touchscreen interface is designed with user-friendly graphics and intuitive controls, allowing operators to easily input and adjust the filling weight. The machine's internal control system then activates the filling mechanism, ensuring accurate and efficient material introduction. This automation not only improves production efficiency but also reduces the potential for human error.

The PLC touchscreen, in conjunction with components and valves sourced from renowned brands, ensures the seamless and reliable operation of the entire machine. The PLC, with its powerful processing capabilities and flexible programming options, coordinates all aspects of the machine's functions. The touchscreen provides a convenient and visual interface for operators to monitor and control the machine. The use of high-quality components and valves from reputable manufacturers minimizes the risk of malfunctions and downtime, enhancing the long-term stability of the machine.

The SPJ50/90/130/160 Batch EPS Pre-expander Machine - A proffers a powerful, efficient, and cost-effective solution for high-quality EPS production. With its sophisticated steam and temperature control systems, automated filling, and low energy consumption, this machine addresses the escalating demands of contemporary EPS foam manufacturers striving to optimize both production and sustainability.

QQ

QQ