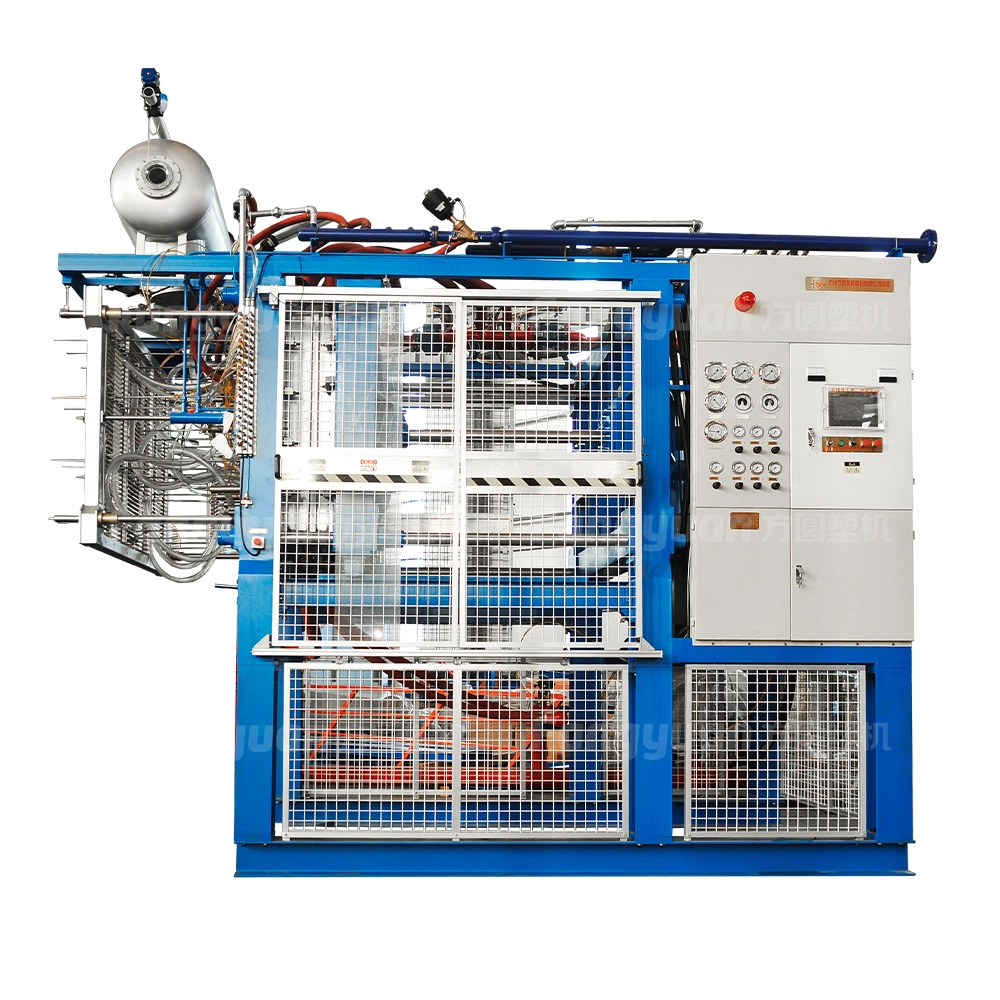

Vacuum EPS Pre-expander Machine for Raw Material Beads

Product Overview

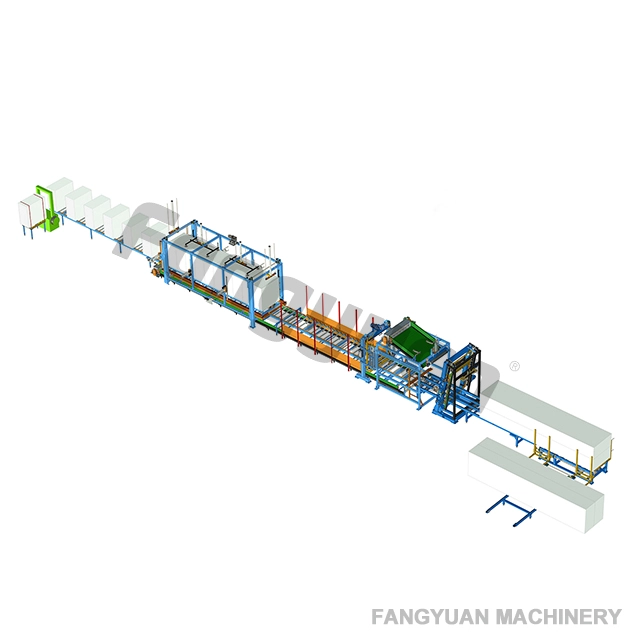

The Vacuum EPS Pre-expander Machine represents a cutting-edge solution for the precise and efficient expansion of EPS (Expanded Polystyrene) beads. Engineered with advanced technology, this machine delivers substantial energy savings, superior product quality, and enhanced operational performance. It is perfectly suited for businesses aiming to streamline their production processes by reducing curing times, improving foam consistency, and minimizing energy consumption.

Key Features

Intelligent Control System

- User-Friendly Interface: The machine is equipped with an intelligent computer control system that provides an intuitive interface for operators to manage and monitor the entire pre-expansion process effortlessly.

- Storable Feeding Formulas: Operators can store multiple feeding formulas for easy retrieval, ensuring consistent and repeatable production runs.

- Remote Updates and Interconnection: Supports remote software updates and interconnection capabilities, facilitating seamless communication between machines in a production line and enabling efficient management of multiple units.

Efficient Heating and Pressurization

- Precise Closed-Loop System: A manual intellectual closed-loop system ensures accurate heating and pressurization within the expansion cylinder, resulting in uniform foaming with minimal fluctuation.

- Energy Savings: By optimizing steam usage, the system reduces steam consumption by up to 30% per ton of material, leading to significant energy savings while maintaining high-quality foam output.

Vacuum Drying Technology

- Accelerated Curing Time: Integrated vacuum drying technology drastically shortens the curing time of EPS beads, increasing the turnover rate of the feeding bin and reducing overall molding duration. This boosts production capacity and streamlines the foam molding process.

Precise Raw Material Weighing System

- Density Weighing and Feedback: The machine features a precise weighing system with density measurement and feedback-based self-adjustment. This ensures accurate raw material measurement and automatic adjustments to maintain optimal foam density, minimizing material waste and ensuring product consistency.

Reliable Components from Global Brands

- High-Quality Parts: To ensure long-term reliability and minimal maintenance, the machine incorporates high-quality components such as valves and electrical parts sourced from globally recognized brands. These premium components guarantee stable operation and durability over time.

Benefits

- Energy Efficiency: Achieve up to 30% less steam consumption per ton of material, significantly reducing energy costs without compromising on production quality.

- Faster Production: Shortened curing times and reduced molding durations enhance throughput and operational efficiency, allowing for higher production volumes.

- Consistent Foam Quality: The precise weighing system ensures consistent foam density and quality, minimizing waste and delivering reliable results every time.

- User-Friendly Operation: An intuitive control system simplifies the learning curve, ensuring smooth and efficient operation even for new or minimally trained operators.

Applications

This machinery finds extensive application across various industries:

- Construction: Producing insulation materials for walls, roofs, and floors.

- Packaging: Manufacturing protective packaging for electronics, appliances, and fragile items.

- Agriculture: Creating lightweight containers for seedling cultivation and crop protection.

- Custom Products: Tailoring EPS blocks to meet specific project requirements.

Technical Support and Service

We offer comprehensive support services, including initial consultation, installation guidance, operator training, and ongoing after-sales service, ensuring your investment yields maximum benefits.

Case Studies

Discover real-world success stories where the Vacuum EPS Pre-expander Machine has played a pivotal role in achieving cost reductions, waste minimization, and productivity improvements. Customer testimonials highlight the reliability and effectiveness of our solutions.

Future Directions

As technology advances, we remain committed to continuously refining our machines, introducing innovations such as enhanced automation, smarter diagnostics, and more sustainable features to stay ahead of industry trends.

Conclusion

The Vacuum EPS Pre-expander Machine is an innovative solution for businesses looking to optimize their EPS bead expansion process. With its intelligent control system, vacuum drying capabilities, and energy-efficient design, it offers unmatched efficiency, quality, and reliability. This machine not only helps reduce operational costs but also enhances product consistency, making it an essential asset for high-performance EPS foam production.

Contact us today to learn more or request a quote!

Conclusion

The EPS Raw Material Batch Pre-expander offers a perfect combination of high efficiency, energy savings, and precise control, making it an excellent choice for businesses looking to optimize their EPS foam production process. With its advanced features, such as precise steam and temperature control and automatic filling system, it ensures high-quality output and reduced operational costs.

For more information or to request a quote, contact us today!

QQ

QQ