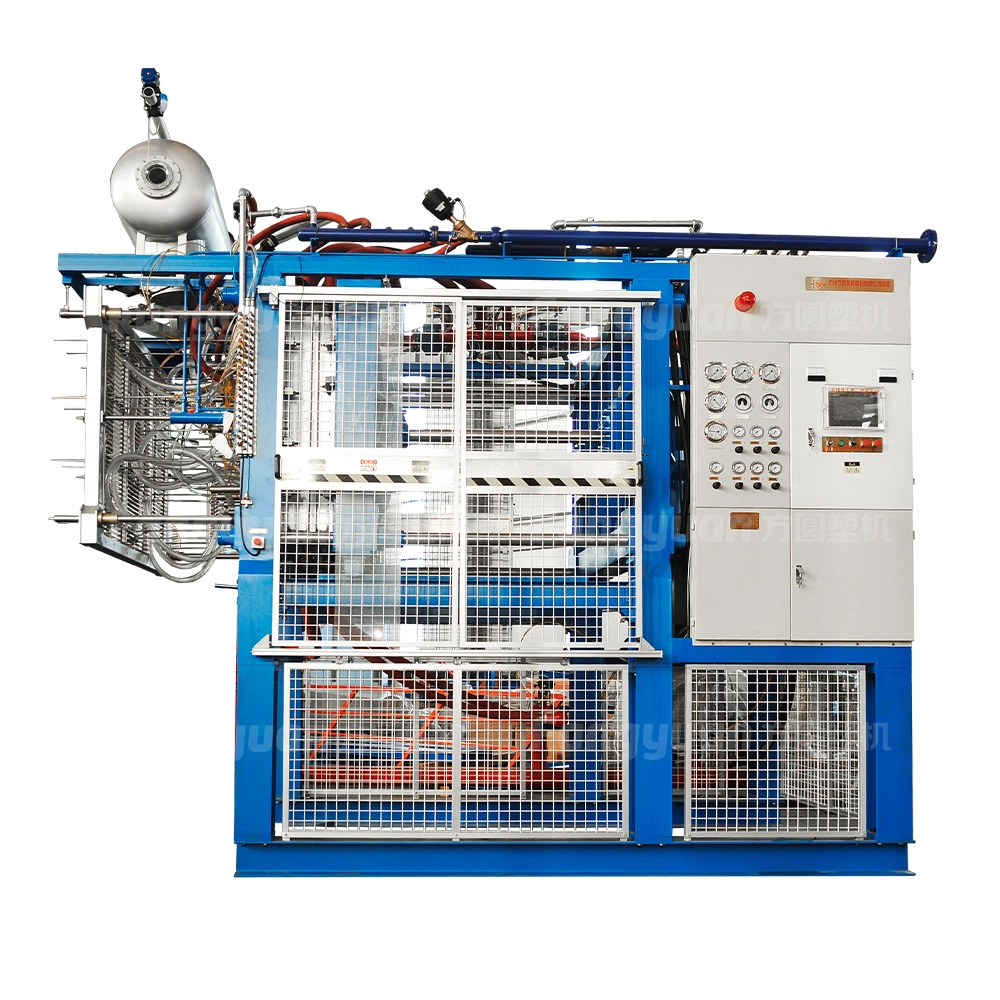

SPB200-600/LF/LZ EPS Polystyrene Block Foam Machinery (Vertical)

Product Overview

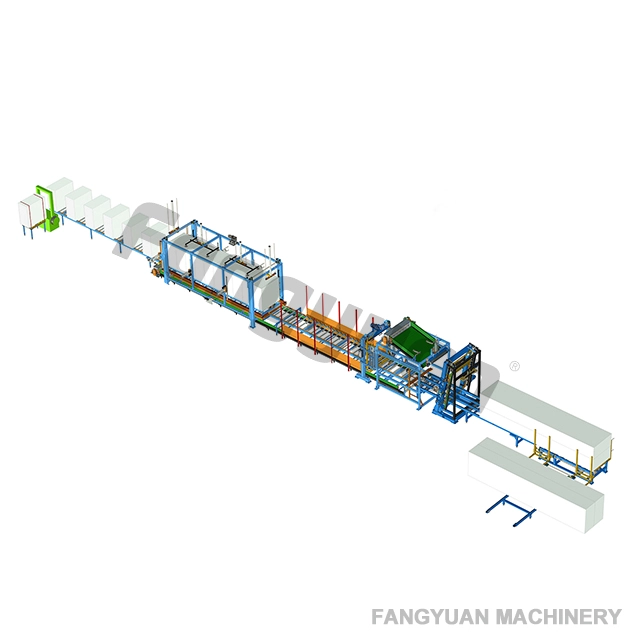

The SPB200-600/LF/LZ EPS Polystyrene Block Foam Machinery (Vertical) is a high-efficiency system designed for rapid, high-output block molding. Available in various specifications and sizes, this machine offers the flexibility to meet diverse production needs. Its robust construction and advanced features ensure long-lasting performance and high-quality foam block production.

Key Features

Machine Structure

- Strong Frame Construction: The machine boasts a high-strength welded frame constructed from rectangular tubes and steel plates, ensuring durability and operational safety.

- Heat-Treated Mould Frames: All mould frames undergo heat treatment to relieve welding stress and prevent deformation, guaranteeing stable performance over the long term.

- Anti-Corrosion Treatment: Post-heat treatment, the mould frames are sandblasted to enhance anti-corrosion properties, extending the life of both the undercoat and finishing coat.

German-Quality Safety Features

- Enhanced Protection: Equipped with three German gauges and safety valves, the machine provides superior protection during operation. It undergoes rigorous water pressure and steam testing to ensure maximum safety and stability throughout the production process.

Steam System

- Energy-Efficient Steam Use: The SPB200-600/LF/LZ model utilizes three ball valves instead of a single large steam valve, resulting in a 20% reduction in steam consumption. ISO-standard butterfly valves further improve the stability and extend the lifespan of the thermocol block moulding machine.

Control System

- User-Friendly Interface: Featuring a Mitsubishi PLC and Schneider touchscreen, the machine offers intuitive operation and control, making it accessible for both experienced and new operators.

- Automatic Process Control:

- Material Level Sensor: Ensures accurate material filling by controlling the filling process.

- Foam Pressure Sensor: Monitors and controls the cooling process, managing the filling, heating, cooling, and opening of the block moulds automatically, minimizing manual intervention.

- Material Level Sensor: Ensures accurate material filling by controlling the filling process.

- Foam Pressure Sensor: Monitors and controls the cooling process, managing the filling, heating, cooling, and opening of the block moulds automatically, minimizing manual intervention.

Vertical Frame Design

- Space-Efficient: The vertical design occupies less floor space, making it ideal for facilities with limited area.

- Improved Moisture Control: Excellent drainage performance significantly reduces moisture content in finished foam blocks, enhancing product quality.

Benefits

- Efficient Production: Rapid molding of foam blocks increases production output within a short period.

- Long Lifespan: Heat-treated mould frames, corrosion-resistant treatments, and high-quality safety components ensure extended operational life.

- Energy Saving: Energy-efficient steam valves reduce steam consumption by up to 20%, lowering operating costs.

- Automatic Operation: The PLC and touchscreen system streamline processes, enabling fully automated operation, reducing manual labor, and boosting productivity.

- Space-Saving Design: The vertical frame structure optimizes space utilization while improving overall machine performance.

Applications

This machinery finds extensive application across multiple industries:

- Construction: Producing insulation panels for walls, roofs, and floors.

- Packaging: Manufacturing protective packaging for electronics, appliances, and fragile items.

- Agriculture: Creating lightweight containers for seedling cultivation and crop protection.

- Custom Products: Tailoring EPS blocks to meet specific project requirements.

Technical Support and Service

We provide comprehensive support services, including initial consultation, installation guidance, operator training, and ongoing after-sales service, ensuring your investment yields maximum benefits.

Case Studies

Explore real-world success stories where the SPB200-600/LF/LZ has played a pivotal role in achieving cost reductions, waste minimization, and productivity improvements. Customer testimonials highlight the reliability and effectiveness of our solutions.

Future Directions

As technology advances, we remain committed to continuously refining our machines, introducing innovations such as enhanced automation, smarter diagnostics, and more sustainable features to stay ahead of industry trends.

Conclusion

The SPB200-600/LF/LZ EPS Polystyrene Block Foam Machinery (Vertical) is a cutting-edge, energy-efficient solution for high-volume foam block production. With advanced steam systems, automatic control, and a durable structure, this machine ensures excellent reliability and cost-effectiveness. Ideal for industries requiring rapid and high-quality block production, it delivers superior results consistently.

Contact us today for more information or to request a quote!

QQ

QQ