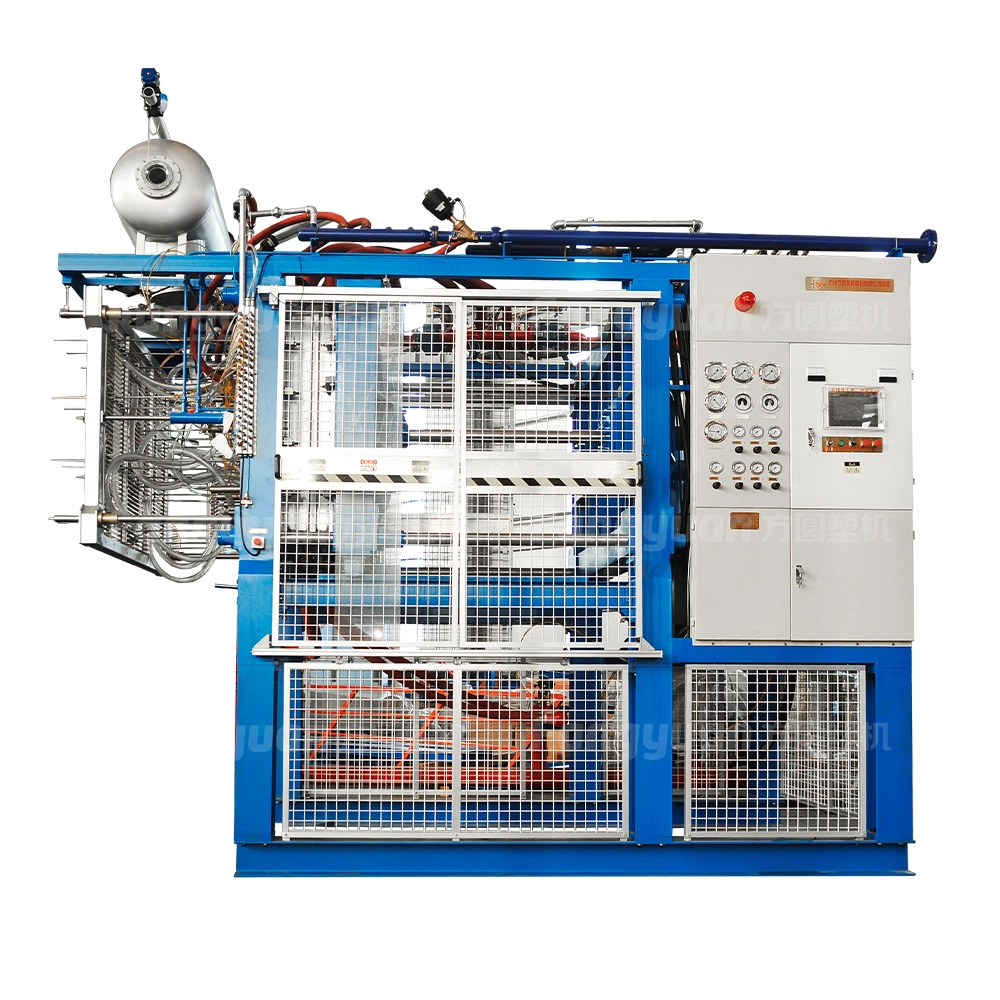

SPB360LZP Fireproofing Insulation EPS Foam Board Machine

Product Description:

The SPB360LZP Fireproofing Insulation EPS Foam Board Machine is a cutting-edge piece of equipment that has been purposefully engineered to manufacture top-notch EPS foam boards, specifically tailored for insulation applications with a particular emphasis on fireproofing capabilities. This remarkable machine amalgamates a suite of advanced technologies, all working in unison to guarantee highly efficient production processes, substantially enhanced energy efficiency, and unrivaled board molding performance. Its user-friendly design philosophy, coupled with a host of innovative features, bestows upon it a level of automation and precision that is second to none, thereby making it eminently suitable to fulfill the exacting and stringent demands of the insulation industry.

Main Features:

- Vertical Sliding Door Structure:

The incorporation of a vertical sliding door structure in this machine represents a significant engineering feat. This design choice not only simplifies the overall operation but also streamlines the material handling procedures. The smooth gliding motion of the vertical doors facilitates rapid and effortless mold opening and closing operations. This, in turn, leads to enhanced productivity as it minimizes the time required between production cycles, allowing for a seamless and continuous manufacturing process. - Multi-Valve Heating System:

The machine is outfitted with a sophisticated multi-valve heating system. This system is engineered to deliver precise, expeditious, and energy-efficient heating. By carefully regulating the flow of heat through multiple valves, it achieves an optimal balance between speed and quality. The ability to heat the materials rapidly without sacrificing the integrity of the foam boards is a key advantage. This results in a significant improvement in production speed while maintaining the highest standards of product quality, ensuring that each board is uniformly heated and molded to perfection. - Optimized Steam Distribution:

The strategic positioning of the steam inlet at the upper part of the machine and the blow-off outlet at the lower part of the mold is a masterstroke of engineering. This layout has been meticulously designed to ensure a rapid heating speed. The steam, as it enters from the top, permeates through the materials in a controlled manner, and the blow-off outlet at the bottom efficiently expels any excess steam or condensate. This synergy results in an excellent molding effect, producing foam boards with a remarkable degree of uniformity. The consistency in the quality of the boards is a direct consequence of this optimized steam distribution mechanism. - Automatic Mixing and De-dusting:

To ensure the production of foam boards of the utmost quality, the machine is equipped with automatic mixing and de-dusting functions. The automatic mixing mechanism ensures that the foam mixture is thoroughly and consistently blended, eliminating any potential inconsistencies in the composition. Simultaneously, the de-dusting function plays a crucial role in removing impurities from the mixture. By purging the raw materials of any foreign particles or contaminants, it significantly enhances the quality and purity of the final product, thereby meeting the most stringent quality standards of the insulation and fireproofing industries. - Adjustable Mold Cavity Sizes:

The size of the board mold cavity in this machine is not fixed but rather compressible. This unique feature allows for a high degree of customization in the production process. Manufacturers can easily adjust the mold cavity to produce foam boards of various dimensions, precisely tailored to meet specific customer requirements. Whether it's a small, intricate board for a specialized application or a large, standard-sized board for mass production, this machine can adapt with ease, providing unparalleled flexibility in production. - Optimized Hydraulic System:

The optimized hydraulic design of the machine is a key factor in its efficient operation. It enables rapid mold closing and opening, a process that is crucial for maximizing production throughput. The simultaneous action of the cylinders ensures that the molds are closed and opened with precision and speed. This allows products to be released from the molds quickly and efficiently, minimizing the time spent in the mold and thereby reducing the overall production cycle time. The hydraulic system is also engineered for reliability and durability, ensuring consistent performance over extended periods of operation. - Snap-on Stainless Steel Permeable Plate:

The machine features a snap-on stainless steel permeable plate structure. This design innovation offers several advantages. Firstly, it simplifies the replacement process. When the permeable plate requires maintenance or replacement, it can be easily detached and replaced without the need for complex tools or extensive downtime. Secondly, it ensures that the steam channels are easily accessible for cleaning. This is essential for maintaining the efficiency of the steam distribution system. By keeping the steam channels clean, the machine can operate at peak performance levels, minimizing the risk of blockages or inefficiencies that could otherwise affect the quality of the foam boards. - Special Vacuum Cooling System:

The incorporation of a special vacuum cooling system sets this machine apart. This system is designed to provide rapid cooling speeds, which is a critical factor in the production of high-quality foam boards. The vacuum cooling process not only cools the boards quickly but also helps maintain their integrity and uniformity. By rapidly reducing the temperature of the foam boards, it helps to set the structure and prevent any deformations or irregularities. This results in foam boards that are not only dimensionally stable but also possess excellent physical properties, making them ideal for insulation and fireproofing applications. - German Butterfly Valves:

The inlet and blow-off valves of the platen are sourced from Germany, renowned for their engineering excellence. These butterfly valves are of the highest quality, ensuring outstanding performance, durability, and efficiency in steam regulation. They are engineered to withstand the rigors of continuous operation and provide precise control over the steam flow. This level of control is essential for maintaining the stability and consistency of the production process, ensuring that the foam boards are heated and cooled in a controlled and uniform manner. - Advanced Steam System:

The steam system of the machine is a marvel of engineering. It is equipped with a steam separator and a relief valve at the inlet. The steam separator plays a crucial role in optimizing the steam quality by removing any moisture or impurities from the steam supply. This ensures that only pure, dry steam is used in the production process, which is essential for achieving consistent results. The relief valve, on the other hand, provides a safety mechanism, ensuring that the steam system operates within a safe pressure range. This combination of components guarantees smooth and reliable operation during the production process, minimizing the risk of any steam-related issues that could disrupt production or affect product quality. - Fully Automated Control:

The control system of the SPB360LZP machine is a paragon of modern automation. It features automatic feedback from a comprehensive array of sensors. These sensors continuously monitor various parameters such as temperature, pressure, and material levels. The data collected is then fed back to the control system, which uses it to enable intelligent, fully automated control of the entire production process. This level of automation ensures precise and consistent production, with minimal operator intervention. The machine can adjust its settings in real-time based on the sensor feedback, optimizing the production process for maximum efficiency and quality. - Automatic Weighing and Drying:

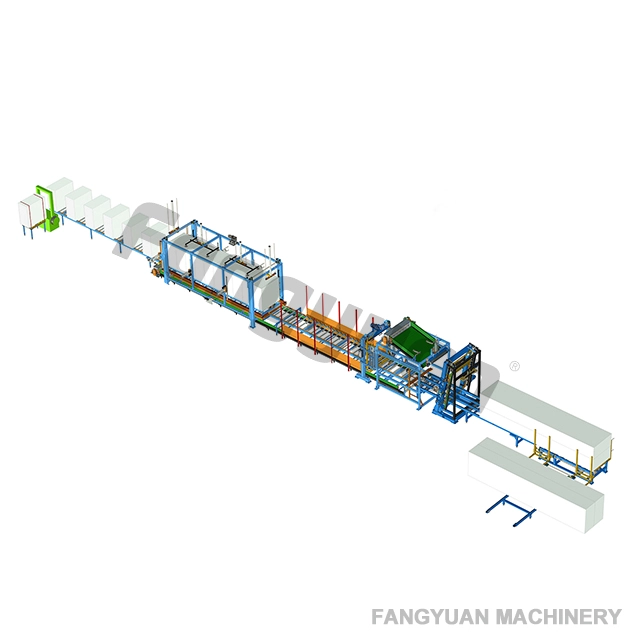

The foam boards produced by this machine are automatically weighed and then seamlessly transferred to the drying system. The automatic weighing function ensures accurate product weight, which is a critical quality parameter. By precisely measuring the weight of each board, manufacturers can ensure that they meet the required specifications. The drying system, which is also automated, further improves the efficiency of the production process. It removes any residual moisture from the boards, enhancing their stability and durability. This integrated weighing and drying process streamlines the production line, reducing the need for manual handling and improving overall productivity.

Benefits:

- Enhanced Heating Efficiency:

The multi-valve heating system and the optimized steam flow work in perfect harmony to achieve enhanced heating efficiency. The precise control over the heat input and the efficient distribution of steam ensure that the materials are heated quickly and uniformly. This not only reduces the overall energy consumption but also results in foam boards with superior physical properties. The improved quality of the boards is a direct result of the optimized heating process, making them more suitable for insulation and fireproofing applications. - Customizable Board Sizes:

The adjustable mold cavity sizes offer a remarkable level of flexibility in production. Manufacturers can easily adapt to changing market demands and customer requirements by producing foam boards of various sizes. This ability to customize the board dimensions not only broadens the range of applications for which the machine can be used but also allows for more efficient use of raw materials. By producing boards that are precisely sized for each application, waste is minimized, and production costs are reduced. - Fast Cycle Time:

The optimized hydraulic system and the vacuum cooling system are the driving forces behind the machine's fast cycle time. The rapid mold closing and opening, combined with the quick cooling process, significantly reduce the time required for each production cycle. This increased production speed translates into higher production capacity without any compromise on the quality of the foam boards. Manufacturers can produce more boards in a shorter period, meeting tight deadlines and increasing their market competitiveness. - High Automation:

The machine's high level of automation, courtesy of features such as automatic feedback control, automatic weighing, and intelligent sensors, is a game-changer. It streamlines the production process, reducing the need for manual labor and minimizing the potential for human errors. The automated control system ensures that each step of the production process is executed with precision and consistency. This not only improves the overall efficiency of the production line but also enhances the quality control of the final product. - Improved Durability:

The use of stainless steel permeable plates and high-quality German valves contributes to the machine's improved durability. These components are designed to withstand the harsh operating conditions of a production environment. The stainless steel plates are resistant to corrosion and wear, while the German valves are engineered for long-term reliability. This durability factor reduces the frequency of maintenance and replacement, resulting in lower operating costs and increased uptime for the machine.

Conclusion:

The SPB360LZP Fireproofing Insulation EPS Foam Board Machine is an exemplary solution for high-performance EPS foam board production. Its energy-efficient design, advanced automation features, and reliable components combine to offer a streamlined and efficient production process. This machine is capable of producing top-quality fireproof and insulating foam boards that meet the most demanding industry standards. It is ideally suited for industrial applications that require high output volumes and uncompromising quality. With its array of features and benefits, it ensures not only efficiency and quality but also long-term durability, making it a wise investment for any business in the insulation and fireproofing sectors.

Contact us today to learn more or request a quote!

Vertical Sliding Door Structure:

The incorporation of a vertical sliding door structure in this machine represents a significant engineering feat. This design choice not only simplifies the overall operation but also streamlines the material handling procedures. The smooth gliding motion of the vertical doors facilitates rapid and effortless mold opening and closing operations. This, in turn, leads to enhanced productivity as it minimizes the time required between production cycles, allowing for a seamless and continuous manufacturing process.

The incorporation of a vertical sliding door structure in this machine represents a significant engineering feat. This design choice not only simplifies the overall operation but also streamlines the material handling procedures. The smooth gliding motion of the vertical doors facilitates rapid and effortless mold opening and closing operations. This, in turn, leads to enhanced productivity as it minimizes the time required between production cycles, allowing for a seamless and continuous manufacturing process.

Multi-Valve Heating System:

The machine is outfitted with a sophisticated multi-valve heating system. This system is engineered to deliver precise, expeditious, and energy-efficient heating. By carefully regulating the flow of heat through multiple valves, it achieves an optimal balance between speed and quality. The ability to heat the materials rapidly without sacrificing the integrity of the foam boards is a key advantage. This results in a significant improvement in production speed while maintaining the highest standards of product quality, ensuring that each board is uniformly heated and molded to perfection.

The machine is outfitted with a sophisticated multi-valve heating system. This system is engineered to deliver precise, expeditious, and energy-efficient heating. By carefully regulating the flow of heat through multiple valves, it achieves an optimal balance between speed and quality. The ability to heat the materials rapidly without sacrificing the integrity of the foam boards is a key advantage. This results in a significant improvement in production speed while maintaining the highest standards of product quality, ensuring that each board is uniformly heated and molded to perfection.

Optimized Steam Distribution:

The strategic positioning of the steam inlet at the upper part of the machine and the blow-off outlet at the lower part of the mold is a masterstroke of engineering. This layout has been meticulously designed to ensure a rapid heating speed. The steam, as it enters from the top, permeates through the materials in a controlled manner, and the blow-off outlet at the bottom efficiently expels any excess steam or condensate. This synergy results in an excellent molding effect, producing foam boards with a remarkable degree of uniformity. The consistency in the quality of the boards is a direct consequence of this optimized steam distribution mechanism.

The strategic positioning of the steam inlet at the upper part of the machine and the blow-off outlet at the lower part of the mold is a masterstroke of engineering. This layout has been meticulously designed to ensure a rapid heating speed. The steam, as it enters from the top, permeates through the materials in a controlled manner, and the blow-off outlet at the bottom efficiently expels any excess steam or condensate. This synergy results in an excellent molding effect, producing foam boards with a remarkable degree of uniformity. The consistency in the quality of the boards is a direct consequence of this optimized steam distribution mechanism.

Automatic Mixing and De-dusting:

To ensure the production of foam boards of the utmost quality, the machine is equipped with automatic mixing and de-dusting functions. The automatic mixing mechanism ensures that the foam mixture is thoroughly and consistently blended, eliminating any potential inconsistencies in the composition. Simultaneously, the de-dusting function plays a crucial role in removing impurities from the mixture. By purging the raw materials of any foreign particles or contaminants, it significantly enhances the quality and purity of the final product, thereby meeting the most stringent quality standards of the insulation and fireproofing industries.

To ensure the production of foam boards of the utmost quality, the machine is equipped with automatic mixing and de-dusting functions. The automatic mixing mechanism ensures that the foam mixture is thoroughly and consistently blended, eliminating any potential inconsistencies in the composition. Simultaneously, the de-dusting function plays a crucial role in removing impurities from the mixture. By purging the raw materials of any foreign particles or contaminants, it significantly enhances the quality and purity of the final product, thereby meeting the most stringent quality standards of the insulation and fireproofing industries.

Adjustable Mold Cavity Sizes:

The size of the board mold cavity in this machine is not fixed but rather compressible. This unique feature allows for a high degree of customization in the production process. Manufacturers can easily adjust the mold cavity to produce foam boards of various dimensions, precisely tailored to meet specific customer requirements. Whether it's a small, intricate board for a specialized application or a large, standard-sized board for mass production, this machine can adapt with ease, providing unparalleled flexibility in production.

The size of the board mold cavity in this machine is not fixed but rather compressible. This unique feature allows for a high degree of customization in the production process. Manufacturers can easily adjust the mold cavity to produce foam boards of various dimensions, precisely tailored to meet specific customer requirements. Whether it's a small, intricate board for a specialized application or a large, standard-sized board for mass production, this machine can adapt with ease, providing unparalleled flexibility in production.

Optimized Hydraulic System:

The optimized hydraulic design of the machine is a key factor in its efficient operation. It enables rapid mold closing and opening, a process that is crucial for maximizing production throughput. The simultaneous action of the cylinders ensures that the molds are closed and opened with precision and speed. This allows products to be released from the molds quickly and efficiently, minimizing the time spent in the mold and thereby reducing the overall production cycle time. The hydraulic system is also engineered for reliability and durability, ensuring consistent performance over extended periods of operation.

The optimized hydraulic design of the machine is a key factor in its efficient operation. It enables rapid mold closing and opening, a process that is crucial for maximizing production throughput. The simultaneous action of the cylinders ensures that the molds are closed and opened with precision and speed. This allows products to be released from the molds quickly and efficiently, minimizing the time spent in the mold and thereby reducing the overall production cycle time. The hydraulic system is also engineered for reliability and durability, ensuring consistent performance over extended periods of operation.

Snap-on Stainless Steel Permeable Plate:

The machine features a snap-on stainless steel permeable plate structure. This design innovation offers several advantages. Firstly, it simplifies the replacement process. When the permeable plate requires maintenance or replacement, it can be easily detached and replaced without the need for complex tools or extensive downtime. Secondly, it ensures that the steam channels are easily accessible for cleaning. This is essential for maintaining the efficiency of the steam distribution system. By keeping the steam channels clean, the machine can operate at peak performance levels, minimizing the risk of blockages or inefficiencies that could otherwise affect the quality of the foam boards.

The machine features a snap-on stainless steel permeable plate structure. This design innovation offers several advantages. Firstly, it simplifies the replacement process. When the permeable plate requires maintenance or replacement, it can be easily detached and replaced without the need for complex tools or extensive downtime. Secondly, it ensures that the steam channels are easily accessible for cleaning. This is essential for maintaining the efficiency of the steam distribution system. By keeping the steam channels clean, the machine can operate at peak performance levels, minimizing the risk of blockages or inefficiencies that could otherwise affect the quality of the foam boards.

Special Vacuum Cooling System:

The incorporation of a special vacuum cooling system sets this machine apart. This system is designed to provide rapid cooling speeds, which is a critical factor in the production of high-quality foam boards. The vacuum cooling process not only cools the boards quickly but also helps maintain their integrity and uniformity. By rapidly reducing the temperature of the foam boards, it helps to set the structure and prevent any deformations or irregularities. This results in foam boards that are not only dimensionally stable but also possess excellent physical properties, making them ideal for insulation and fireproofing applications.

The incorporation of a special vacuum cooling system sets this machine apart. This system is designed to provide rapid cooling speeds, which is a critical factor in the production of high-quality foam boards. The vacuum cooling process not only cools the boards quickly but also helps maintain their integrity and uniformity. By rapidly reducing the temperature of the foam boards, it helps to set the structure and prevent any deformations or irregularities. This results in foam boards that are not only dimensionally stable but also possess excellent physical properties, making them ideal for insulation and fireproofing applications.

German Butterfly Valves:

The inlet and blow-off valves of the platen are sourced from Germany, renowned for their engineering excellence. These butterfly valves are of the highest quality, ensuring outstanding performance, durability, and efficiency in steam regulation. They are engineered to withstand the rigors of continuous operation and provide precise control over the steam flow. This level of control is essential for maintaining the stability and consistency of the production process, ensuring that the foam boards are heated and cooled in a controlled and uniform manner.

The inlet and blow-off valves of the platen are sourced from Germany, renowned for their engineering excellence. These butterfly valves are of the highest quality, ensuring outstanding performance, durability, and efficiency in steam regulation. They are engineered to withstand the rigors of continuous operation and provide precise control over the steam flow. This level of control is essential for maintaining the stability and consistency of the production process, ensuring that the foam boards are heated and cooled in a controlled and uniform manner.

Advanced Steam System:

The steam system of the machine is a marvel of engineering. It is equipped with a steam separator and a relief valve at the inlet. The steam separator plays a crucial role in optimizing the steam quality by removing any moisture or impurities from the steam supply. This ensures that only pure, dry steam is used in the production process, which is essential for achieving consistent results. The relief valve, on the other hand, provides a safety mechanism, ensuring that the steam system operates within a safe pressure range. This combination of components guarantees smooth and reliable operation during the production process, minimizing the risk of any steam-related issues that could disrupt production or affect product quality.

The steam system of the machine is a marvel of engineering. It is equipped with a steam separator and a relief valve at the inlet. The steam separator plays a crucial role in optimizing the steam quality by removing any moisture or impurities from the steam supply. This ensures that only pure, dry steam is used in the production process, which is essential for achieving consistent results. The relief valve, on the other hand, provides a safety mechanism, ensuring that the steam system operates within a safe pressure range. This combination of components guarantees smooth and reliable operation during the production process, minimizing the risk of any steam-related issues that could disrupt production or affect product quality.

Fully Automated Control:

The control system of the SPB360LZP machine is a paragon of modern automation. It features automatic feedback from a comprehensive array of sensors. These sensors continuously monitor various parameters such as temperature, pressure, and material levels. The data collected is then fed back to the control system, which uses it to enable intelligent, fully automated control of the entire production process. This level of automation ensures precise and consistent production, with minimal operator intervention. The machine can adjust its settings in real-time based on the sensor feedback, optimizing the production process for maximum efficiency and quality.

The control system of the SPB360LZP machine is a paragon of modern automation. It features automatic feedback from a comprehensive array of sensors. These sensors continuously monitor various parameters such as temperature, pressure, and material levels. The data collected is then fed back to the control system, which uses it to enable intelligent, fully automated control of the entire production process. This level of automation ensures precise and consistent production, with minimal operator intervention. The machine can adjust its settings in real-time based on the sensor feedback, optimizing the production process for maximum efficiency and quality.

Automatic Weighing and Drying:

The foam boards produced by this machine are automatically weighed and then seamlessly transferred to the drying system. The automatic weighing function ensures accurate product weight, which is a critical quality parameter. By precisely measuring the weight of each board, manufacturers can ensure that they meet the required specifications. The drying system, which is also automated, further improves the efficiency of the production process. It removes any residual moisture from the boards, enhancing their stability and durability. This integrated weighing and drying process streamlines the production line, reducing the need for manual handling and improving overall productivity.

The foam boards produced by this machine are automatically weighed and then seamlessly transferred to the drying system. The automatic weighing function ensures accurate product weight, which is a critical quality parameter. By precisely measuring the weight of each board, manufacturers can ensure that they meet the required specifications. The drying system, which is also automated, further improves the efficiency of the production process. It removes any residual moisture from the boards, enhancing their stability and durability. This integrated weighing and drying process streamlines the production line, reducing the need for manual handling and improving overall productivity.

Enhanced Heating Efficiency:

The multi-valve heating system and the optimized steam flow work in perfect harmony to achieve enhanced heating efficiency. The precise control over the heat input and the efficient distribution of steam ensure that the materials are heated quickly and uniformly. This not only reduces the overall energy consumption but also results in foam boards with superior physical properties. The improved quality of the boards is a direct result of the optimized heating process, making them more suitable for insulation and fireproofing applications.

The multi-valve heating system and the optimized steam flow work in perfect harmony to achieve enhanced heating efficiency. The precise control over the heat input and the efficient distribution of steam ensure that the materials are heated quickly and uniformly. This not only reduces the overall energy consumption but also results in foam boards with superior physical properties. The improved quality of the boards is a direct result of the optimized heating process, making them more suitable for insulation and fireproofing applications.

Customizable Board Sizes:

The adjustable mold cavity sizes offer a remarkable level of flexibility in production. Manufacturers can easily adapt to changing market demands and customer requirements by producing foam boards of various sizes. This ability to customize the board dimensions not only broadens the range of applications for which the machine can be used but also allows for more efficient use of raw materials. By producing boards that are precisely sized for each application, waste is minimized, and production costs are reduced.

The adjustable mold cavity sizes offer a remarkable level of flexibility in production. Manufacturers can easily adapt to changing market demands and customer requirements by producing foam boards of various sizes. This ability to customize the board dimensions not only broadens the range of applications for which the machine can be used but also allows for more efficient use of raw materials. By producing boards that are precisely sized for each application, waste is minimized, and production costs are reduced.

Fast Cycle Time:

The optimized hydraulic system and the vacuum cooling system are the driving forces behind the machine's fast cycle time. The rapid mold closing and opening, combined with the quick cooling process, significantly reduce the time required for each production cycle. This increased production speed translates into higher production capacity without any compromise on the quality of the foam boards. Manufacturers can produce more boards in a shorter period, meeting tight deadlines and increasing their market competitiveness.

The optimized hydraulic system and the vacuum cooling system are the driving forces behind the machine's fast cycle time. The rapid mold closing and opening, combined with the quick cooling process, significantly reduce the time required for each production cycle. This increased production speed translates into higher production capacity without any compromise on the quality of the foam boards. Manufacturers can produce more boards in a shorter period, meeting tight deadlines and increasing their market competitiveness.

High Automation:

The machine's high level of automation, courtesy of features such as automatic feedback control, automatic weighing, and intelligent sensors, is a game-changer. It streamlines the production process, reducing the need for manual labor and minimizing the potential for human errors. The automated control system ensures that each step of the production process is executed with precision and consistency. This not only improves the overall efficiency of the production line but also enhances the quality control of the final product.

The machine's high level of automation, courtesy of features such as automatic feedback control, automatic weighing, and intelligent sensors, is a game-changer. It streamlines the production process, reducing the need for manual labor and minimizing the potential for human errors. The automated control system ensures that each step of the production process is executed with precision and consistency. This not only improves the overall efficiency of the production line but also enhances the quality control of the final product.

Improved Durability:

The use of stainless steel permeable plates and high-quality German valves contributes to the machine's improved durability. These components are designed to withstand the harsh operating conditions of a production environment. The stainless steel plates are resistant to corrosion and wear, while the German valves are engineered for long-term reliability. This durability factor reduces the frequency of maintenance and replacement, resulting in lower operating costs and increased uptime for the machine.

The use of stainless steel permeable plates and high-quality German valves contributes to the machine's improved durability. These components are designed to withstand the harsh operating conditions of a production environment. The stainless steel plates are resistant to corrosion and wear, while the German valves are engineered for long-term reliability. This durability factor reduces the frequency of maintenance and replacement, resulting in lower operating costs and increased uptime for the machine.

QQ

QQ